Company Infrastructure | Infrastructure Systems of Prakash Laser

Prakash relies heavily on technology upgrades for keeping a competitive edge. Perhaps, this explains the consistent replacement of conventional manufacturing equipments with modern machineries resulting in increased production efficiency, consistence quality of components, and timely delivery.

Most advanced CAD/ CAM software (NX) for design and manufacturing process is being used. This ensures consistent and flawless performance.

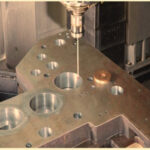

Company has got one of the most sophisticated machine shop having CNC machine, HMC, VMC, Grinder, Lathes, all of which cater for achieving high standards.

Our vast experience with high-precision manufacturing technologies and complex work pieces enables us to promise you one-stop, quality manufacturing of a diverse range of parts. Everything from proper assembly to precise inspection has been well taken care of by our engineers using modern tools and machines like CMM (Coordinates Measuring Machines).

Company employs highly skilled workers with extensive experience in every aspect of manufacturing. Our team of R&D, production and marketing works hand in hand to study the demands of printing industry and ensures individual attention to various customers.

Some of the Machines in our company:

- 4-axis VMC-fanuc robodrill, japan (2 No.)

- 3-axis VMC-BFW, India

- 3-axis VMC-jyoti, India

- 3-axis VMC- Kitamura, Japan (2 No.)

- CNC lathe-takisawa, japan

- CNC lathe-ACE, India (4 No.)

- CNC lathe-LMW,India (2 No.)

- CNC lathe- kingsbury, UK

- CNC lathe-HMT,India

- CNC Grinder-HMT,India

- HMC- Nigata, Japan

- 5-axis deckle Maho 200 P, Germany

- 4-axis VMC-Haas, V5, USA

- 3-axis VMC-fulland Alpha, Taiwan

- VMC, Kitamura, Japan

- CMM- Carl Zeiss, Germany