Overview

Laser for automobile industry equip engineers with a powerful, precision tool of light, which has already made inroads across other sectors. Like other automobile-centred technologies such as hybrid electric engines, telematics, and GPRS, the laser tool is a breath of fresh air. The simplicity of automating laser instruments and incorporating them into the processing chain scales down production costs and renders thorough output. The laser tool snugly fits into the automotive engineer’s toolbox for it has long dominated other technologies in engraving, welding, marking or drilling. It outshines its rivals with scalpel-like accuracy, efficiency, and production line security.

Laser Marking

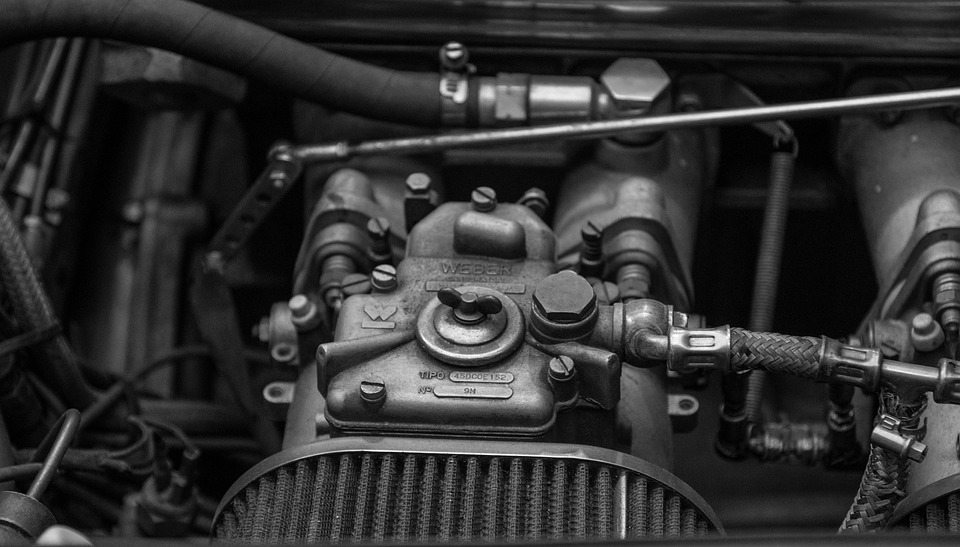

Precise and uniform marks act as flagpole features for the automotive industry due to consistency in traceability for security reasons. Today, laser marking, Laser for automobile industry equip engineers with a powerful device for etching intelligent alphanumeric, data matrix codes, and serial numbers on all manner of materials along the automotive production chain.

Autopart Marking Sample by Prakash Laser

See more samples, Visit our gallery of Laser marking on Auto Parts

Laser markings remain durable and outlast cars or components after coming into contact with extreme temperatures and fluids like gas or oil. Tamper-proof traceability and ID to distinguish parts and components with laser marking provides a host of benefits over conventional marking and engraving techniques.

Benefits of Laser Machining Tools;

- High-Precision Marking with super quality imprints, even on the delicate interface, one-point fonts and little marks with eligibility.

- Durable marking, abrasion-proof, and heat-resistant for long-lasting, indelible and traceable logos

- High marking speed is achievable with laser-powered processes and streamlining the production line

Laser Engraving

Laser tools slice all types of materials incisively, including glass, plastic, and metal with pinpoint precision unmatched by other cutting techniques. Industrial laser engraving in the automotive sector offers flexibility and ultra-precision engraving, contamination-and-taint proof cuts, and superior quality cut with no additional finishing needed. With an ever-growing list of metals and alloys for automotive manufacturing engineering, lasers yield a flexible, intense and lightning-fast technique for cutting.

Autopart Marking Sample

View more samples of laser marking and engraving by Prakash Laser

It also provides precision cuts for a variety of materials used in the manufacture of automobiles. It shines by engraving the interior and functional components like ambient lighting and fitting, headlights, display and much more. Laser technology scales down the component expenditure and assembly chain giving automakers an edge in a competitive global market. For new, intelligent and multifunctional materials, you need a high-precision tool like a laser for non-contact cutting.

No doubt laser marking provides the best option to mark auto parts!

About Us

A rapidly growing laser technology developer in India, we supply automakers Laser for automobile industry configurations and a vast collection of applications. Safety, ergonomics, energy efficiency and environmental preservation have become part of our theme to keep pace with the dynamics of the automobile industry. We dominate in the supply of laser marking and laser engraving machining tools destined for the automotive industry in India and yonder. Laser machines consummate automotive production lines by diminishing cycle times, creating precision results and attain improved productivity while slashing off the cost per unit.

Other Uses in the Automotive Sector

Laser technologies have also become useful in advanced laser alloying, coating, polishing, shock-ossifying, CNC laser machining, and rapid laser prototyping. Laser systems handpicked with the appropriate energy source offer flexibility and durability for more straightforward and tailored solutions.