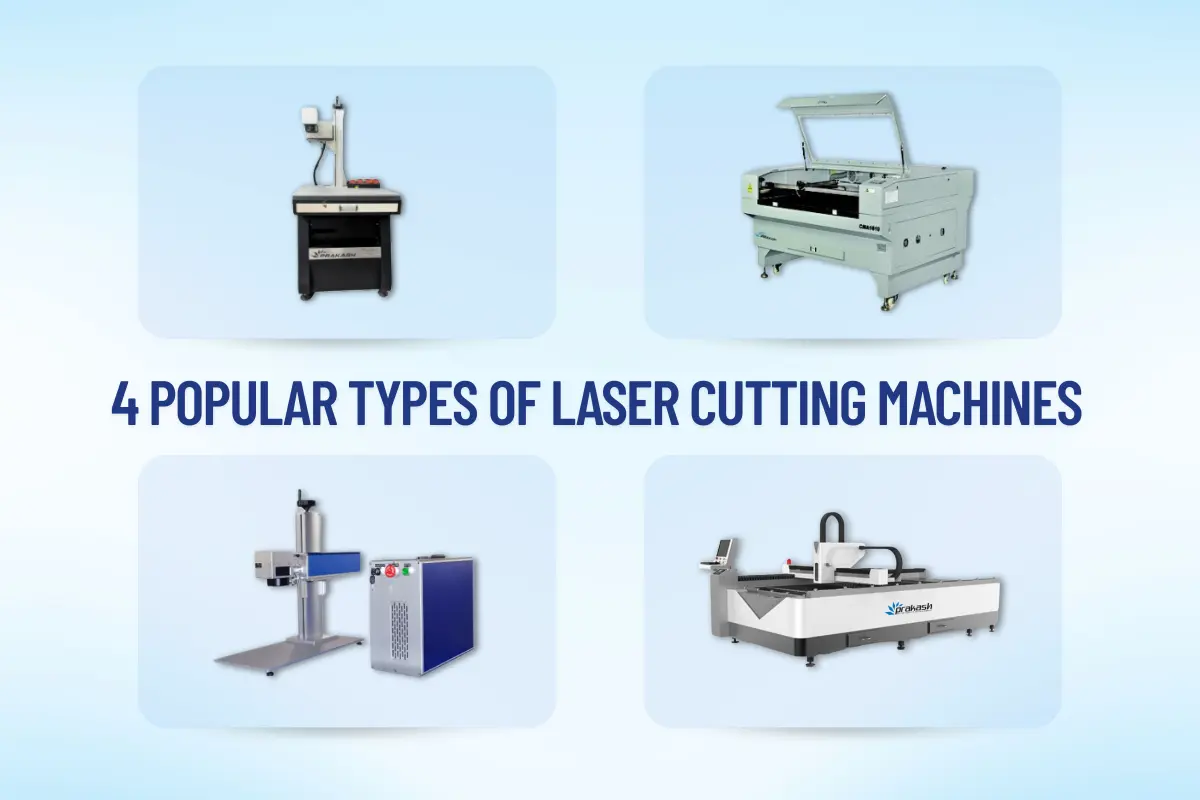

Choosing the right types of laser cutting machines isn’t just about the specs—it’s about what actually works for your material, your shop, and your output needs. Whether you’re running a signage business, a fabrication unit, or a custom furniture setup, knowing which types of laser cutters are out there (and what they’re built for) makes a big difference.

At Prakash Laser, we focus on machines that are proven to work, reliable, efficient, and backed by solid support. Here’s a breakdown of 4 popular options we offer so you can stop browsing and start building.

The Different Types Of Laser Cutting Machines You Should Know About

1. Fiber Laser Cutting Machine

If you’re looking for a laser that cuts metal, this is it.

Fiber laser cutting machines are designed for speed, precision, and clean edges when working with metals like mild steel, stainless steel, aluminium, and copper. They’re used across industries that need fast, high-volume production.

Why it works:

- Faster than traditional CO2 lasers for metal.

- Lower running costs—no mirrors, no gas refills.

- A compact design with fewer moving parts leads to less maintenance.

Common uses:

- Metal fabrication

- Automotive components

- Industrial enclosures

- Signboards

2. CO2 Laser Cutting Machine (Glass Tube)

Not everything’s about metal. If your work involves acrylic, MDF, leather, wood, or fabric, a CO2 laser cutting machine with a glass tube is a solid bet.

Why it’s popular:

- Delivers clean, smooth cuts—especially for curved or delicate designs.

- Doesn’t char or burn through edges when properly calibrated.

- Great value for entry-level businesses or signage makers.

Best for:

- Acrylic letters and shapes

- Wood crafts and partitions

- Laser-cut fashion items

- Packaging prototypes

This type of laser cutting machine is also widely used by DIY businesses, educational institutions, and custom gift shops. It’s one of the most affordable and easy-to-use types of laser cutting machine.

3. Mix Head Cutting Machine

Ever needed to cut both metal and non-metal on the same day, in the same space, using just one machine?

That’s where this hybrid machine comes in.

What it does:

This dual-function laser cutter can switch between materials—cutting stainless steel one minute and acrylic the next. It’s perfect for businesses that offer mixed material services or don’t want to invest in two separate machines.

Who it’s for:

- Signage and display units

- Interior decor firms

- Job shops and prototyping businesses

Why it matters:

- Saves space and money

- One machine, two use cases

- Easy to switch modes

If you need one setup to handle everything from MDF to thin gauge steel, this is one of the smartest types of laser cutters to consider.

4. Laser Engraving and Marking Machines

Let’s say you don’t need to cut just engrave, mark, or label. That’s where these machines shine.

What they do:

Engraving and marking machines use either fiber or CO2 laser sources to create permanent marks on a range of surfaces, including metals, plastics, wood, and leather.

Why choose this type?

- No contact with the material and no wear and tear.

- High-speed marking with clean precision.

- Ideal for logos, QR codes, serial numbers, and branding.

Use cases include:

- Electrical and electronics industries

- Promotional products

- Auto parts

- Tool and die sets

If you’re in the business of precision branding, these machines handle it effortlessly. And yes, you can choose between fiber laser marking (for metals) and CO2 marking (for organics and plastics).

Which One Should You Choose Among The Different Types Of Laser Cutting Machines?

- If you work primarily with metal, go for a fiber laser cutting machine.

- If you cut non-metal materials like acrylic or MDF, a CO2 glass tube laser is perfect.

- Want both? Get the hybrid CO2 metal + non-metal laser.

- And if you’re only engraving, marking, or labeling, stick to laser marking machines.

Each of these types of laser cutters serves an obvious purpose. The right one depends on your material, your volume, and your budget.

Want To See These Popular Laser Machines In Action?

At Prakash Laser, we don’t just sell machines. We guide you through the process, install everything, train your team, and stay with you post-sale.

✔ Free installation and training

✔ Warranty-backed machines

✔ Made for Indian industries

✔ Customisation available

✔ Factory-direct pricing

Contact us today to discuss your cutting needs or get a quote for any of the machines above. Whether it’s for acrylic sheets or lasers that cut through metal, we’ve got something that fits your workflow. Let’s get you the right machine!

5 thoughts on “4 Popular Types of Laser Cutting Machines You Should Know”

Comments are closed.