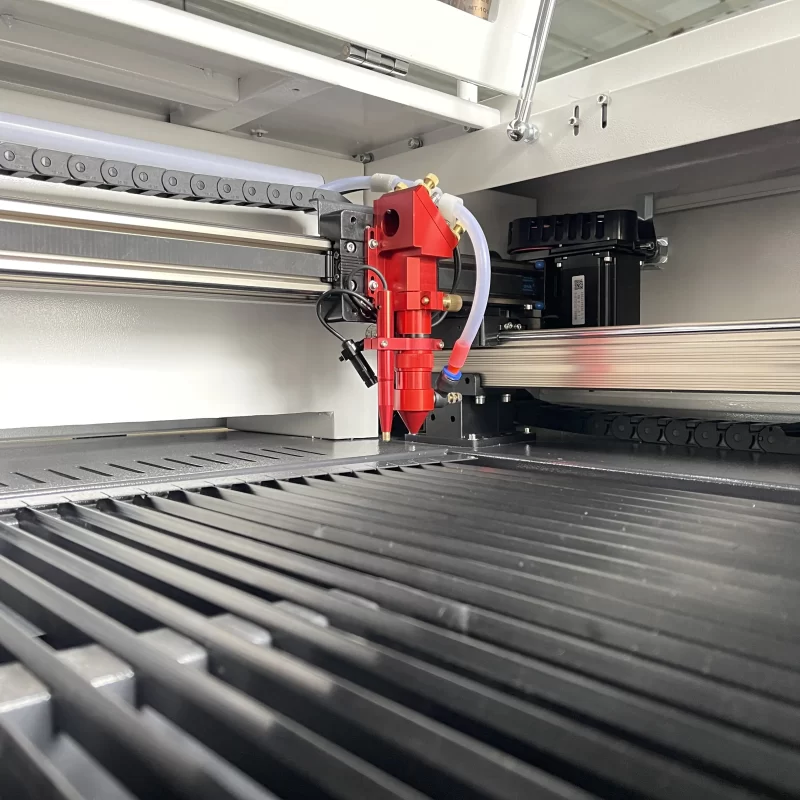

Grab Premium CO2 Laser Cutting Head For Your Laser Systems

A CO2 Laser Cutting Head is a key component that directs and focuses the 10.6 µm laser beam onto your material, delivering clean, precise cuts and engravings. Built with high-quality mirrors, a precision focusing lens, and an assist-gas nozzle, it ensures stable beam delivery and smooth cutting performance. Designed for durability and consistent operation, this CO2 Laser Cutting Machine head is compatible with a wide range of laser systems and ideal for users who demand accuracy, reliability, and long-lasting results.

Key Internal Components:

- Focusing Lens

- Nozzle

- Mirrors

- Adjustable Mount

| Description | |

|---|---|

| Material | Carbon Steel |

| Frequency | 60Hz |

| Voltage | 110V |

| Usage/Application | CO2 Laser Machine |

| Lens Diameter | 25 mm |

| Mirror Diameter | 20 mm |

What Are The Main Functions Of A CO2 Laser Cutting Head?

Here are some key functions of a Laser Cutting Head:

- Beam Focusing: The Laser Cutting Head uses a focusing lens to spread a wide laser beam into a tiny spot. This high-energy point enables the melting or vaporization of even materials with high melting points.

- Nozzle Gas Flow: The head uses a controlled-assist gas system that delivers oxygen, nitrogen, or compressed air through the nozzle to the cutting area. This helps boost cutting speed and clears away molten material, leaving a cleaner edge.

- Height Sensing: With built-in sensors, the laser head can automatically adjust its Z-axis height. This keeps the focal distance constant, even when the material thickness changes, ensuring precise cutting.

- Heat-Control Cooling: Many laser cutting heads use a water-cooling system to protect the internal lenses from heat. Water from a chiller circulates through the head to keep the temperature cool and stable.

- Path Accuracy Control: A final mirror inside the laser head redirects the beam downward through the focusing lens and onto the material.

Easy Maintenance Tips!

Here are some simple yet effective tips for maintaining your Laser Cutting Head on a Double Head Laser Cutting Machine:

- Make sure to clean the lenses regularly with the proper solution and remove any smoke residue to prevent lens damage.

- Check periodically that the laser beam is perfectly aligned at the nozzle center.

- Also, ensure the nozzle is free from clogs so the assist gas can flow correctly.

Ready To Buy A CO2 Laser Cutting Head? Choose Prakash Laser!

We understand the importance of choosing the right laser cutting head for your Dual Head Laser Cutting Machine. Reliable cutting performance depends not only on the laser source but also on the quality and compatibility of the CO2 laser cutting head. That’s where Prakash Laser comes in.

We support a wide range of industrial requirements with machines and spare parts engineered to meet high precision standards. This focus on quality is why many industry leaders continue to rely on us.

If pricing is a concern, we offer cost-effective laser cutting head options that allow you to invest with confidence. And there’s more:

- Contact us today to book a demo. Our team of experts will guide you through every step of the process.

- The technology we offer is proudly made in India.

- Check out our list of esteemed clients across various industries and feel confident in choosing us.

Now, get ready to experience cutting-edge technology and take your operations to the next level.

Frequently Asked Questions

1. What materials are compatible with a CO2 Laser Cutting Head?

CO2 laser cutting heads can cut and engrave a variety of materials, including wood, acrylic, plastics, leather, fabrics, and certain metals, when paired with the right power and settings.

2. How frequently should I clean the laser cutting head?

Lenses and nozzles of your laser cutting head should be cleaned regularly, typically weekly to monthly, or every 20–30 hours of use. Always use the recommended cleaning solutions to remove smoke residue and prevent clogging for optimal performance.

3. Are these Laser cutting heads compatible with dual-head technology?

Yes, our Laser Cutting Head works seamlessly with dual-head laser systems.