Laser Marking Technology changes the way you can work with different materials, but finding the best option for you is necessary because no machine is perfect and has its pros and cons. Choosing from the debate of UV vs Fiber vs CO2 Laser Marking technology can significantly impact the quality, speed, and precision of your work. This article will discuss the different types of Laser Marking Machine and the difference between CO2 and Fiber and UV Laser, ensuring you can choose the best one for your specific needs.

Table of Contents:

1. Fundamental Difference Between CO2 And Fiber And UV Laser

2. The Applications of UV vs Fiber vs CO2 Laser Marking Machines in Different Industries

3. UV vs Fiber vs CO2 Laser Marking: A Quick Comparison

4. Final Words – Choosing Between UV vs Fiber Vs CO2 Laser Marking Machines

Fundamental Difference Between CO2 And Fiber And UV Laser

In UV vs Fiber vs CO2 Laser Marking, the main difference lies in the wavelength of each laser. Short wavelengths, like in UV lasers, offer high energy and fine marking on delicate materials. Fiber lasers work best for high‑contrast marks on metals, while CO2 lasers excel on non‑metals such as glass, wood, and acrylic. Understanding the difference between CO2 and Fiber and UV laser is a primary factor you should be looking for in the actual machine specifications.

UV Laser Marking Machines –

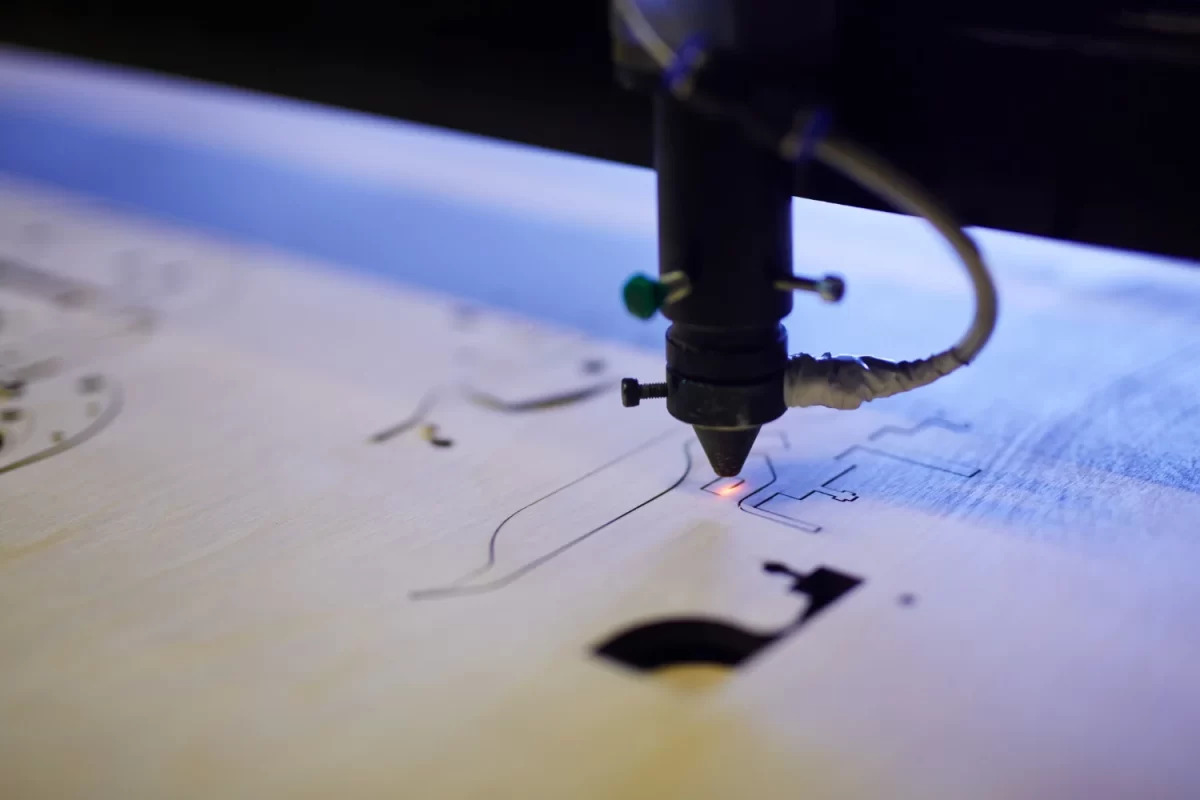

UV laser marking machines are designed for high‑precision marking on intricate, heat‑sensitive materials. Operating at a wavelength of around 355 nm, these machines use a cold marking process that minimizes the chances of making any hot spots on the surface, making them perfect for plastics, specialty glass, medical devices, and micro‑electronics. The shorter wavelength offers a high absorption rate, ensuring crisp, high‑contrast marks even on transparent or reflective surfaces.

Pros

- Outstanding, high‑resolution marking capability

- No thermal damage — perfect for sensitive materials

- Works well on transparent and reflective surfaces

- Excellent for micro‑engraving and intricate designs

Cons

- Higher cost compared to CO2 and Fiber machines

- Slower marking speed for large‑area jobs

- Best suited for specific niche applications rather than heavy bulk marking

Fiber Laser Marking Machines

Fiber Laser Marking Machines are engineered for high‑speed, high‑contrast marking on metals and some industrial plastics. Operating at a wavelength of 1064 nm, these machines use a fiber‑optic delivery system that produces exceptional and high-intensity beam quality and marking precision. The longer wavelength of this laser, compared to UV lasers, is highly absorbed by metals, making it ideal for deep engraving and black marking. This characteristic might make this machine better in the “UV laser vs Fiber laser” competition.

Pros

- High-speed marking speed for high‑volume production

- Excellent contrast on metals

- Low maintenance and long lifespan

- Capable of deep engraving and black marking

Cons

- Not suitable for transparent materials like glass or acrylic

- Less effective on heat‑sensitive plastics compared to UV lasers

- Higher cost than some CO2 machines for similar marking sizes

CO2 Laser Marking Machines

CO2 Laser Marking Machines are highly effective for marking and even engraving on non‑metal materials. Operating at a wavelength of 1064 mm, they use gas laser technology to deliver precise results on wood, glass, acrylic, plastics, paper, leather, and ceramics. CO2 systems excel on the surfaces where fiber lasers cannot mark efficiently.

CO2 lasers are often chosen as the best laser marking method for packaging, signage, glass marking, and decorative engraving.

Pros

- Excellent for non‑metals and organic materials

- Cost‑effective for large marking areas

- High‑quality engraving with polished edges on acrylic

- Versatile across many industries

Cons

- Not effective on metals without coating

- Lower precision compared to UV lasers for micro‑marking

- The bulkier machine size in some models makes it hard to move.

The Applications Of UV vs Fiber vs CO2 Laser Marking Machines In Different Industries

Fiber Laser Marking Machines are ideal for metal marking in automotive, aerospace, and electronics industries, from engraving serial numbers on engine parts to deep marking titanium bolts or coding electronic connectors.

CO2 Laser Marking Machines excel in non‑metal applications, such as marking expiration dates on food packaging, engraving glass bottles, or cutting intricate wooden designs for furniture and décor.

UV Laser Marking Machines are perfect for high‑precision marking on delicate, heat‑sensitive materials like silicon wafers, medical devices, and cosmetic packaging, ensuring crisp marks without any heat damage.

By now, the unique advantages and limitations of each machine should be clearer, helping you determine which suits your specific requirements.

UV vs Fiber vs CO2 Laser Marking: A Quick Comparison

| Feature/ Factor | UV Laser Marking Machine | Fiber Laser Marking Machine | CO2 Laser Marking Machine |

| Marking Style | Ultra fine, high contrast, “cold marking” | Deep engraving, high contrast, permanent marks | Surface engraving, cutting, and decorative marking |

| Wavelength | 355nm (short wavelength) | 1064mm (long wavelength) | 1064mm (long wavelength) |

| Precision | Very high | high | Medium – high |

| Speed | Moderate | Very fast (ideal for high volume production) | Fast for non-metal marking |

| Cost Range | High (specialized applications) | Moderate‑high | Moderate |

| Limitations | Slower on large area jobs, higher cost | Limited to transparent and glass materials | Cannot mark bare metals effectively |

Read Blog: What Is The Difference Between CO2 Laser Engraving Machine And CO2 Laser Marking?

Final Words – Choosing Between UV vs Fiber Vs CO2 Laser Marking Machines

When it comes to picking the right Laser Marking machine, it’s all about getting the best laser marking method, matching the tool to your material and production goals. UV Lasers are designed to mark on delicate surfaces and heat-sensitive materials. Fiber Lasers fit in when you need fast, permanent marking on metals, while CO2 Lasers are ideal for versatile non‑metal applications. Knowing these strengths makes it easier to choose the solution that serves your purpose while fitting your workflow best.

Ready to find the right laser marking machine for your needs? Browse our complete selection and take the next step in upgrading your production.