Have you been searching for a perfect machine that helps you achieve precise shapes and flawless designs? Chances are you’ve come across two popular options: die cutting and laser cutting. While both serve the same goal, they’re very different in how they work. So, what sets them apart? What are their advantages, limitations, and results? Let’s discuss the details and figure out which one, Die Cutting vs Laser Cutting, is the right choice for your needs.

What Is Die Cutting?

Wondering “how to use a die cut machine?” and “what is a die cutting machine?” We’ve got all the answers.

Die cutting is a traditional manufacturing method that relies on a custom-made die to cut, shape, or stamp materials into exact designs. Think of the die as a mold or stencil that delivers consistent results. This process is especially efficient for the high-volume production of uniform shapes and is commonly used with materials such as paper, cardboard, fabric, rubber, leather, plastics, and even thin metals.

Important Insights:

- Mechanism: Die cutting uses pressure to press the material against the die, producing clean and consistent shapes.

- Types: Flatbed die (stationary) and rotary die (rotating for continuous production).

- Applications: Packaging, stickers, textiles, industrial components, and crafts.

- Advantages: Ideal for mass production, fast output, consistent shapes, and low per-unit cost.

- Limitations: Less flexibility for complex or customized designs, as new dies are required for each shape.

What Is Laser Cutting?

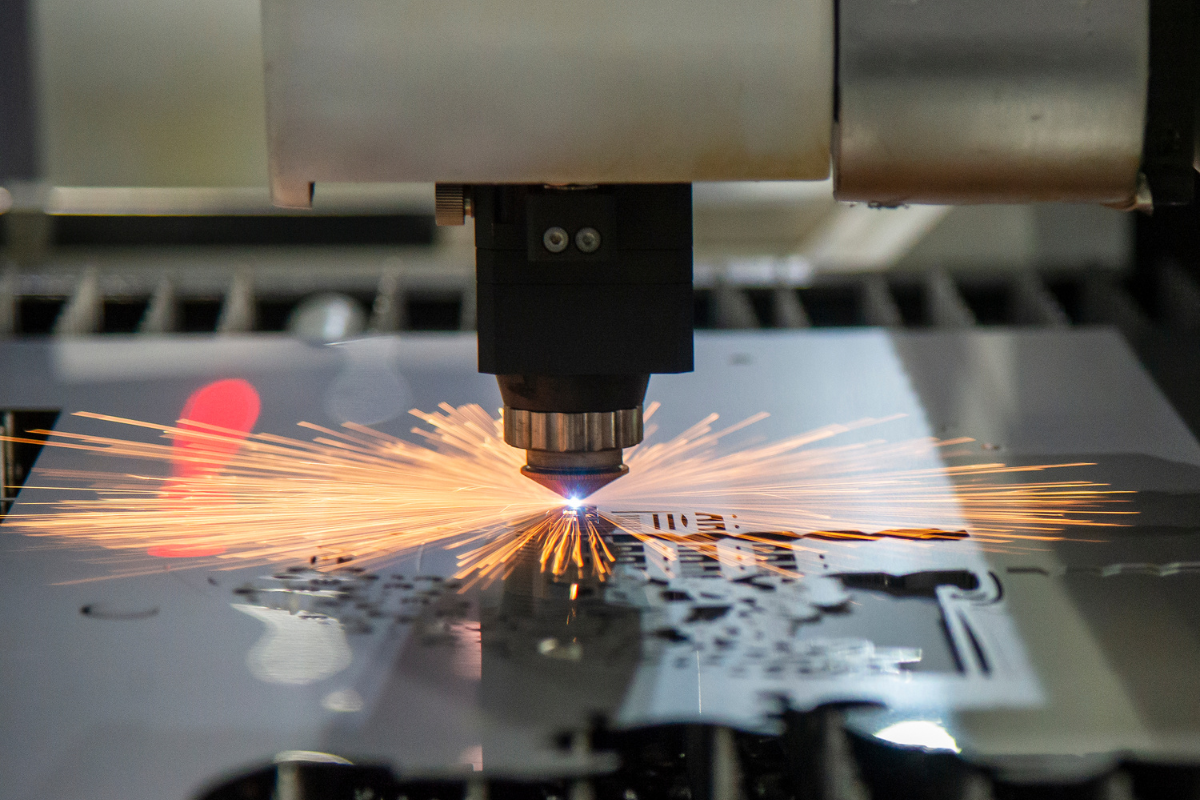

Laser cutting uses a high-powered, focused laser beam to cut materials with extreme precision. This contactless technology is controlled by a computer (CNC), allowing the laser to follow a programmed path to melt or burn through the material.

A stream of gas clears away debris during the process, leaving smooth, clean edges with minimal material distortion.

Important Insights:

- Mechanism: Uses a high-powered, focused, contactless laser beam to cut, engrave, or etch materials along a defined path.

- Types: CO2 lasers, Fiber lasers, and Diode/UV lasers.

- Applications: Signage, automotive parts, electronics, jewelry, textiles, packaging, and prototyping.

- Advantages: Excellent for intricate designs, minimal tool wear, and flexibility for prototyping or low- to medium-volume production.

- Limitations: Slower for very large volumes, possible slight edge burning, higher initial setup costs, and requires proper ventilation.

What Is The Difference Between Die Cut And Laser Cut?

Here’s a detailed comparison to help you understand the key differences between die cutting vs laser cutting:

| Feature | Die Cut | Laser Cut |

|---|---|---|

| Set up | Requires a custom die for each shape | No physical die needed; shapes are programmed via software |

| Design flexibility | Limited flexibility | Highly flexible |

| Material depth | Excellent for thicker materials and multi-layer stacks | Limited thickness; may require multiple passes |

| Maintenance | High maintenance | Lower maintenance |

| Cost-effectiveness | Very cost-effective for high volumes | Less economical for extremely large volumes |

| Speed | Extremely fast once the die is set | Fast for complex patterns but slower for large runs of simple shapes |

Die Cutting Vs Laser Cutting: Which One Is Right For You?

The answer depends on your specific requirements. When choosing between die cutting vs laser cutting, consider factors such as production volume, material type, design complexity, and budget.

Die cutting is the better option for large-scale production of simple, repetitive shapes—especially when working with softer materials. It offers speed and cost efficiency once the die is in place.

Laser cutting, on the other hand, excels in precision, flexibility, and customization. It is ideal for intricate designs, prototyping, and low- to medium-volume production across a wide range of industries.

And if laser cutting is the solution you’re looking for, let Prakash Laser be your trusted partner. Our heavy-duty laser machines deliver global-standard precision backed by advanced R&D. Book a demo today and let us handle the rest. Partner with us and take your business to the next level. Contact us now!