The world of EV manufacturing is growing faster than ever, and so is the demand for technologies that can keep pace. Automakers now require innovative production methods for EV components that deliver greater precision, speed, efficiency, and cost-effectiveness at scale.

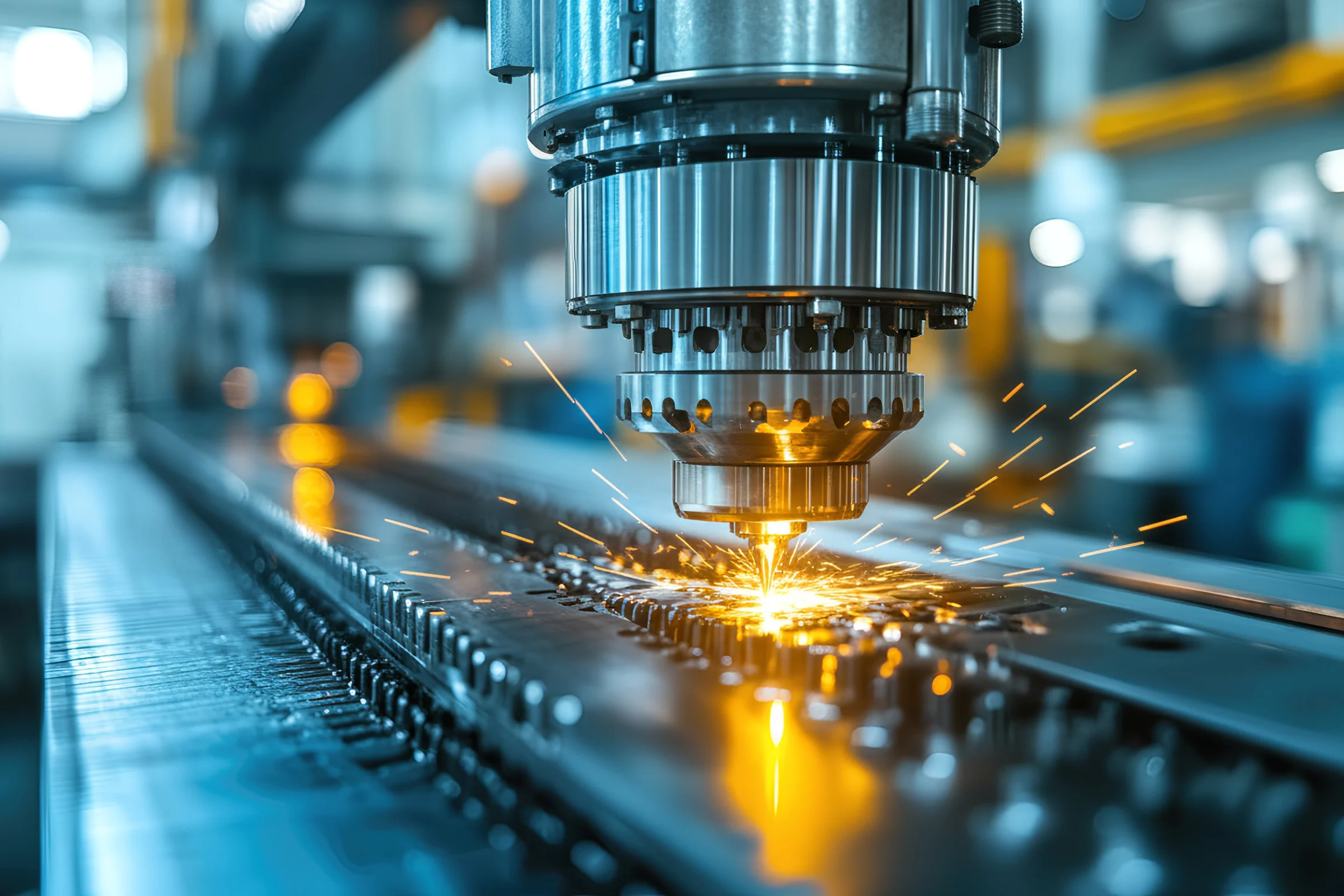

This is where advanced laser systems step in, redefining how EV components are cut, welded, marked, and manufactured, with massive advantages in EV battery production. Let’s take a closer look at how laser machines are powering this transformation.

Table Of Contents

Understanding The EV Boom: Key Insights!

The EV boom is powered by the worldwide push to reduce carbon emissions and combat climate change. This shift has encouraged manufacturers to rethink critical components for electric vehicles, such as electric motors, battery packs, lightweight frames, and power electronics.

However, the EV industry still faces hurdles, including limited charging infrastructure, concerns over battery life and driving range, and the relatively high cost of EVs.

This is where laser machines for EV batteries come into play, and the good news is, they’re making a real difference. Advanced laser technology has improved precision, efficiency, and safety in EV battery manufacturing and supports better battery recycling, making the entire EV manufacturing ecosystem more sustainable.

Why Laser Machines Are Becoming Essential In EV Manufacturing

Here are some of the key features that make Laser Machines essential in EV manufacturing:

Precision & Repeatability In EV Parts

The contactless, highly repeatable laser process ensures precise, consistent, high-quality welds and cuts, especially for sensitive EV components. Plus, it minimizes defects and reduces material wastage.

Faster Production Cycles

Laser systems integrate seamlessly into automated production lines, increasing manufacturing speed and efficiency to keep up with the growing demand for EVs.

Design Flexibility

EV laser manufacturing enables more complex and compact designs, such as tab-less battery cells, which offer higher energy capacity and range. This wasn’t easy to achieve with traditional methods.

Cost Optimization

EV manufacturing is becoming more cost-optimized as higher accuracy rates reduce the need for rework, lower energy consumption, decrease manual labor requirements, and cut down maintenance costs.

Energy Efficiency

Lastly, laser-based manufacturing is an energy-efficient, sustainable solution that generates less waste and reduces the overall carbon footprint of EV production.

Key Laser Applications Transforming EV Manufacturing

Laser Cutting and Laser Marking are two core technologies that play a key role in EV manufacturing. Let’s take a closer look at how each contributes to the process:

Laser Cutting

A Laser Cutting Machine enables manufacturers to work with high-strength steel and lightweight aluminum frames, as well as with complex geometries required for EV chassis. It delivers clean edges and provides consistent repeatability.

It also supports laser tab welding, pouch cell sealing, and the precise joining of copper and aluminum components. Because it minimizes heat distortion, it ensures a stronger, safer, and more reliable system for ‘electric vehicle battery manufacturing with laser’.

Laser Marking

A Laser Marking Machine enables permanent QR codes, serial numbers, and tracking details on battery components. This ensures traceability throughout the EV lifecycle. It also supports anti-counterfeit measures by producing tamper-proof, high-precision markings that safeguard product authenticity.

It also lets manufacturers create ultra-precise holes for cooling channels and thermal management systems.

Read more: Laser Marking Has Found Its Way in the Automotive Industry!

How Global Leaders Use Laser Machines In EV Manufacturing: Case Studies

There are three major players in the EV manufacturing industry. Let’s take a look at how they’re making the most of laser technology:

Tesla

One of the biggest names in the EV world, Tesla uses laser welding to create strong, reliable battery modules, an approach that’s inspiring EV makers worldwide, including in India.

BYD

The Chinese automaker BYD uses high-speed laser cutting to build sturdy EV frames, demonstrating how this technology can boost EV production in India.

Volkswagen

These German-engineered Volkswagen EVs use laser automation to boost speed and efficiency, an approach that India’s EV industry is also adopting.

In Conclusion!

In conclusion, laser machines play a central role in the ongoing evolution of EV manufacturing. They support innovation, improve production efficiency, and deliver consistent, high-quality results at scale. As EV manufacturing continues to grow, advanced laser systems are expected to remain an important part of building efficient and more sustainable production processes.

Frequently Asked Questions

1. Is laser technology suitable for mass-producing EVs?

Yes, laser machines can scale efficiently and deliver consistent, quality results for high-volume EV manufacturing.

2. Can laser technology shape the future of EVs in India?

Yes, laser systems can shape the future of Indian EV manufacturing by enabling faster, more precise, and more durable, sustainable production techniques.

3. Is laser technology suitable for improving battery production?

Yes, laser cutting, welding, and marking improve battery assembly precision, safety, and traceability while supporting recycling.