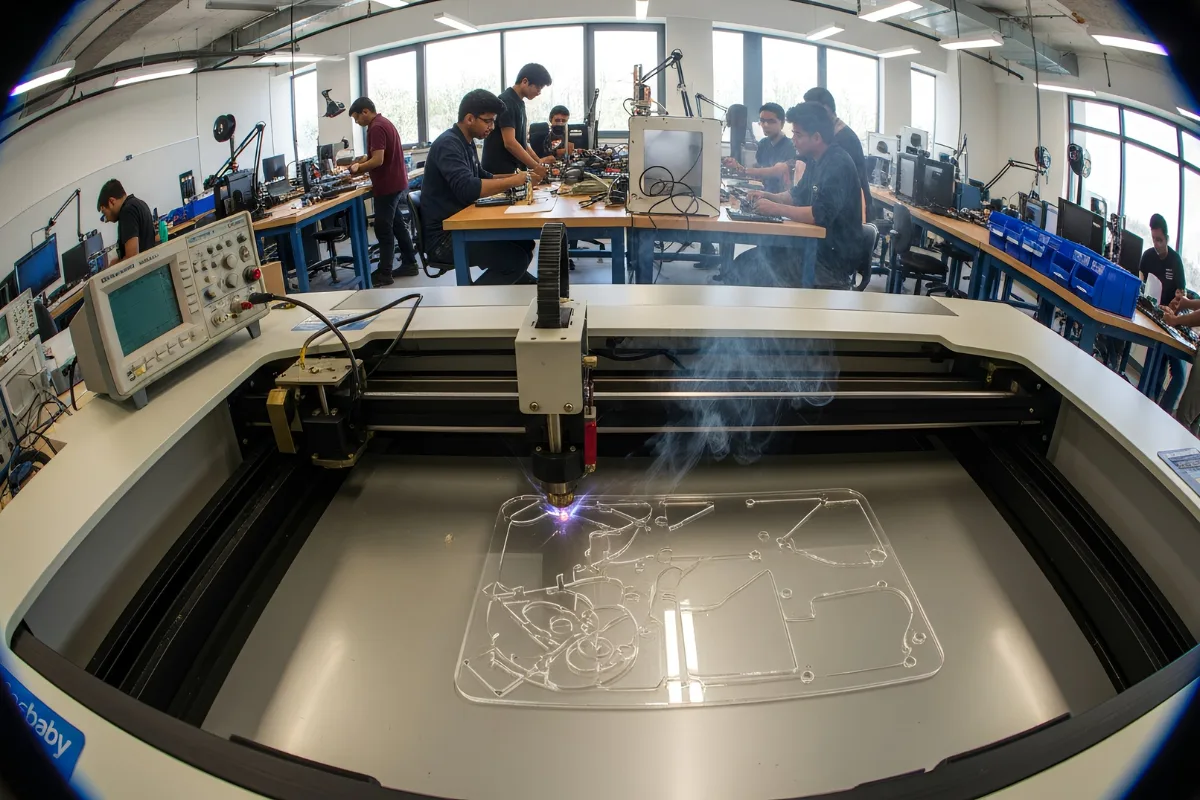

The All India Council for Technical Education (AICTE) IDEA Lab is transforming education by making advanced prototyping tools accessible to students across institutions. Designed to bridge the gap between theory and hands-on learning, these labs encourage a practical, innovation-first approach to education, especially among engineering institutions.

And by integrating technologies such as CO2 laser cutting, IDEA Labs enable students to create precise, real-world prototypes rather than limiting learning to simulations or textbooks. Let’s explore CO2 laser cutting for prototyping works, why it matters (specifically in engineering education), and its long-term impact on innovation and skill development.

Table Of Contents

- Why Is CO2 Laser Cutting Ideal For Educational Institutions?

- IDEA Lab: How CO2 Laser Benefits Engineering Students

- IDEA Lab: Applications of CO2 Laser Cutting Machine for Students

- Why Modern Fabrication Tools Work Better For Engineering Education

- Safety Parameters For CO2 Laser Machines In College Labs

- Why Choose Prakash Laser for AICTE IDEA Labs?

- Final Takeaways: Long-Term Impact on Engineering Education

Why Is CO2 Laser Cutting Ideal For Educational Institutions?

A CO2 Laser Cutting Machine is perfect for educational institutions for the reasons below:

Fast Design-to-Output Learning

In an AICTE IDEA Lab, with CO2 Laser Cutting Machines, rapid design-to-output workflows enable fast learning. The digital designs are quickly converted into physical outputs using CAD files, authoring tools, and pre-set templates, avoiding the delays of traditional fabrication methods.

Making Advanced Prototyping Affordable

They also enable affordable, shared access to advanced prototyping tools. Through makerspaces and institutional labs, students can use technologies such as laser cutters, 3D printers, and design software to build, test, and refine prototypes before moving to production.

Encourages Experimentation

By minimizing setup time and iteration cycles, such machines encourage experimentation, an advantage that benefits students and even motivates them to build their own startups. These labs serve as rapid laser cut prototyping hubs, giving students hands-on experience in quickly turning their CAD designs into real-world models without relying on external services.

Supports Multiple Engineering Disciplines

These machines support multiple engineering disciplines by processing a wide range of materials and integrating seamlessly with Computer Numerical Control (CNC)–based systems. They deliver consistent precision across applications in textile, mechanical, electrical, and civil engineering prototyping.

IDEA Lab: How CO2 Laser Benefits Engineering Students

IDEA Lab, along with the CO2 Laser technology, supports the broader education sector, but engineering students benefit most from its hands-on, technology-driven approach. Let’s take a closer look at how the facility is transforming engineering education:

- Mechanical engineering students can rapidly design and fabricate parts, fixtures, and functional models for testing and validation.

- Electronics engineering students can develop precise enclosures, panels, and mounting components, improving system integration and hands-on understanding of the subject.

- Electrical engineering students can support product design and prototype development for innovative hardware-based ideas.

- Final-year projects across multiple engineering disciplines can be completed more efficiently, enabling students to meet timelines and participate in innovation challenges and competitions.

Applications of CO2 Laser Cutting Machine for Students

Here are the primary applications of CO2 Laser Cutting Machines for students across various engineering and design disciplines:

1. Rapid Prototyping (All Engineering Branches)

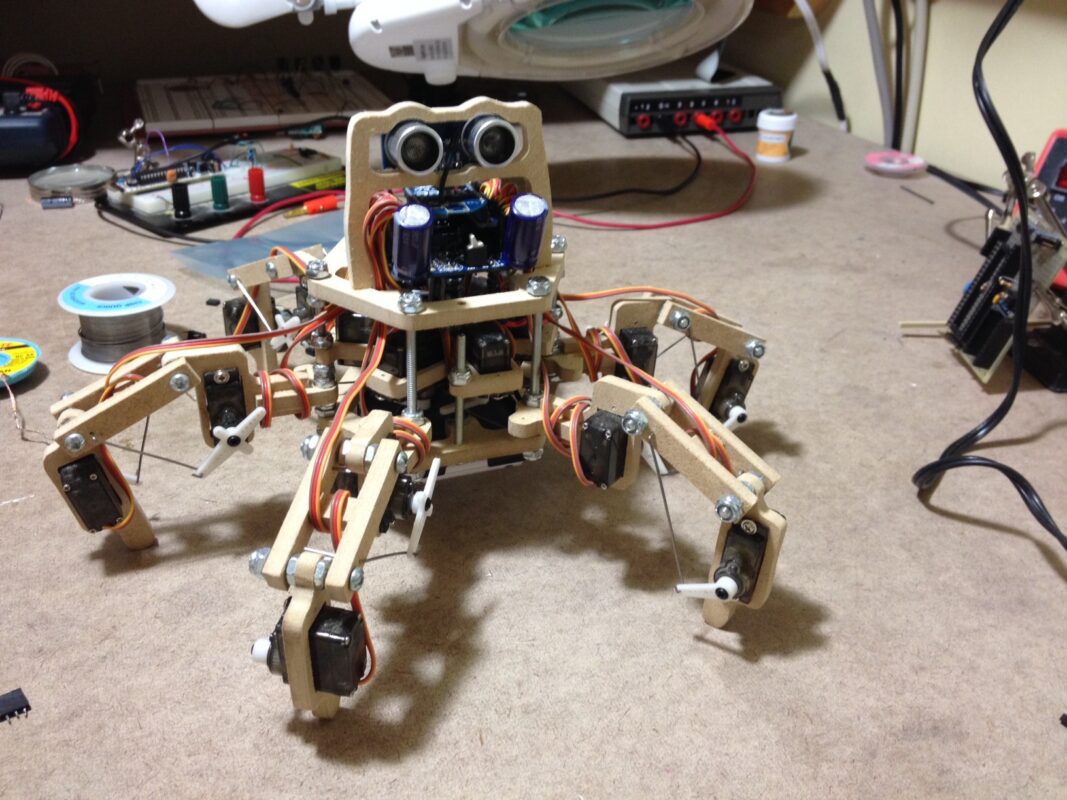

The most common use is creating functional prototypes. Students can design parts in CAD software and cut them out of MDF or Acrylic to test fit, form, and function before moving to expensive metal manufacturing.

- Mechanical: Gears, linkages, robot chassis, and pulley systems.

- Electronics: They make custom mdf boxes to hold their circuit boards and small clips to hold sensors in place.

2. Architectural & Civil Scale Modeling

Architecture and Civil Engineering students use CO2 lasers to create highly detailed scale models of buildings, bridges, and urban layouts.

- Precise cutting of walls, windows, and roof trusses.

- Engraving textures like brickwork, grass, or stone onto the material surface.

3. DIY Robotics & Drones

The lightweight nature of acrylic and thin plywood makes them perfect for student robotics.

- Chassis Design: Cutting custom frames for wheeled robots or hexapods.

- Drone Frames: Prototyping lightweight quadcopter frames to test aerodynamics and motor mounting.

4. Fashion & Textile Innovation

In interdisciplinary IDEA Labs, fashion technology students use the laser for “Digital Craft.”

- Intricate Lace Work: Cutting complex patterns on silk, denim, or synthetic fabrics that would be impossible by hand.

- Leather Goods: Precision cutting and engraving for wallets, belts, and footwear prototypes.

Why Modern Fabrication Tools Work Better For Engineering Education

A CO2 Laser Cutting Machine offers a significant edge over traditional fabrication tools for engineering students. Here’s how:

| Aspect | CO2 Laser Cutting | Traditional Fabrication Method |

| Learning curve | Shorter learning curve with software-driven operation | Steeper learning curve involving manual skills |

| Tooling requirements | No physical tooling, molds, or dies required | Requires jigs, molds, dies, or manual fixtures |

| Design-to-output speed | Direct CAD-to-cut workflow enables rapid prototyping | Longer setup time due to tooling and manual preparation |

| Precision and repeatability | High accuracy with consistent repeatability | Varies based on operator skill and tool condition |

| Material flexibility | Suitable for acrylic, wood, rubber, textiles, and plastics | Often limited to specific materials per tool |

| Batch production for students | Efficient for producing identical parts for multiple teams | Time-consuming for repeated or batch fabrication |

| Classroom suitability | Safe, controlled, and repeatable for academic labs | Less predictable for large student groups |

| Iteration and experimentation | Easy design changes with minimal downtime | Design changes often require retooling |

Safety Parameters For CO2 Laser Machines In College Labs

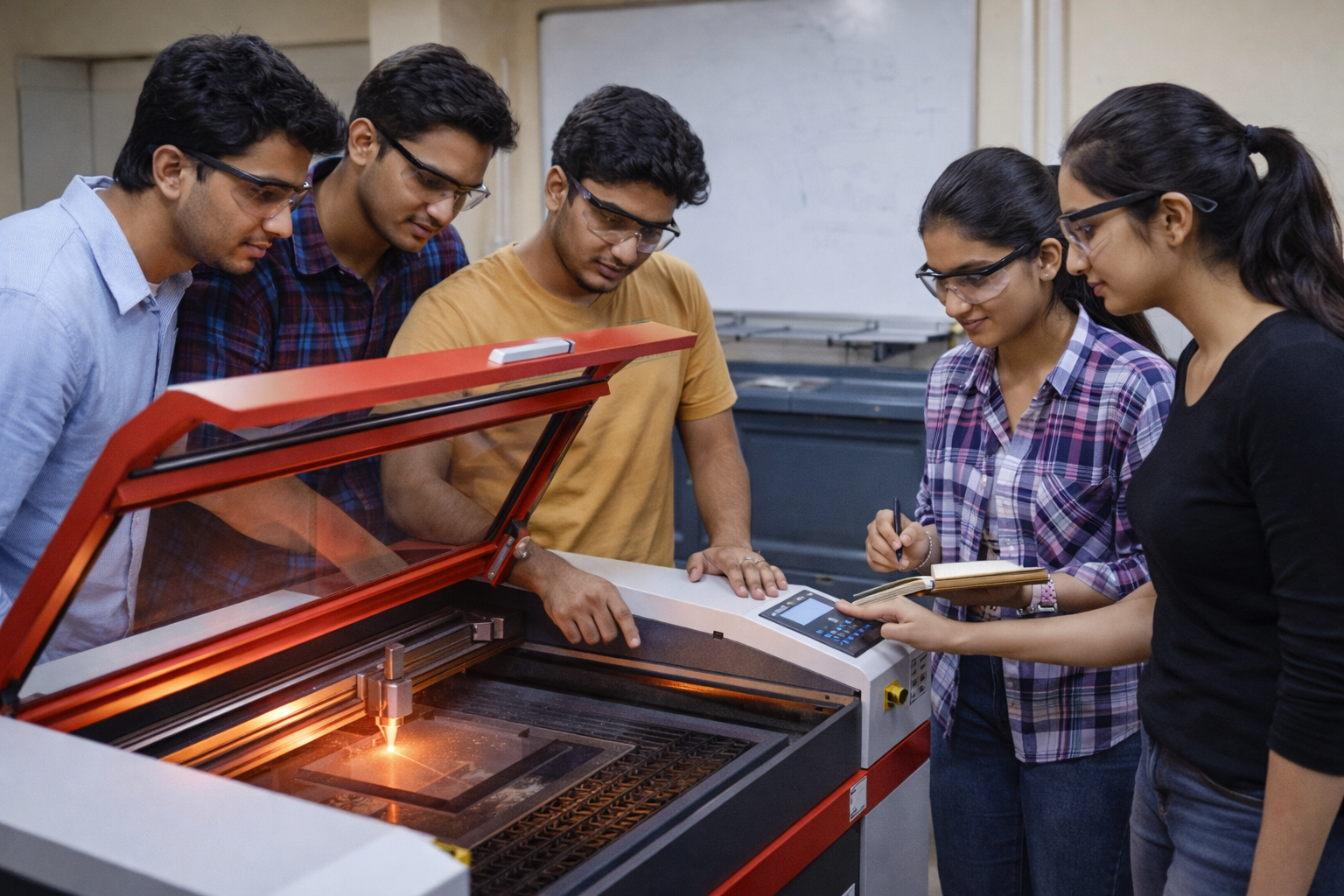

Beyond workflow efficiency and educational benefits, students must also follow these essential safety parameters when experimenting with CO2 laser machines:

- Work only with enclosed lasers and avoid direct exposure to the beam.

- Make sure the lab’s ventilation and fume extraction systems are on.

- Use only materials approved for laser cutting and avoid experimenting with unapproved materials.

- Complete all training, follow the lab’s SOPs, and operate the machine under supervision.

- Report issues and ensure machines are regularly checked and maintained.

Why Choose Prakash Laser for AICTE IDEA Labs?

As a pioneer in laser technology for over 20 years, Prakash Laser understands the unique requirements of educational institutions and research facilities. Here is why our CO2 Laser machines are the preferred choice for IDEA Labs across India:

- Robust Build for High Usage: Educational labs often involve continuous, heavy-duty usage by multiple batches of students. Our machines are engineered with industrial-grade components to ensure durability and long-term reliability.

- User-Friendly Software Integration: We provide intuitive software interfaces that bridge the gap between CAD designs and physical prototypes. This minimizes the learning curve for students, allowing them to focus on innovation rather than troubleshooting.

- Unmatched Safety Standards: Safety is paramount in a student environment. Prakash Laser machines come equipped with advanced safety features, including enclosed cabinets, emergency stop buttons, and efficient fume extraction systems to ensure a risk-free learning experience.

- Comprehensive Training & Support: We don’t just deliver a machine; we empower educators. Prakash Laser provides detailed hands-on training for faculty and lab assistants, ensuring they can guide students effectively. Our pan-India service network ensures that any technical issues are resolved promptly to minimize lab downtime.

- Versatility in Prototyping: From intricate architectural models to mechanical gears and electronic enclosures, our machines handle a vast array of materials (acrylic, wood, fabric, MDF, and more), making them the perfect “all-in-one” tool for multi-disciplinary IDEA Labs.

- Proven Track Record: With successful installations at prestigious institutions like Pearl Academy, IIT Delhi, IIT Bombay and various engineering colleges, Prakash Laser has a proven track record of fostering student creativity through reliable technology.

Final Takeaways: Long-Term Impact on Engineering Education

Laser-based rapid prototyping has a significant long-term impact on engineering education by equipping students with industry-ready skills and fostering a culture of innovation. Access to tools like CO2 laser cutters allows learners to develop practical problem-solving abilities, improve designs quickly, and gain hands-on experience in modern manufacturing processes.

AICTE IDEA Labs represents this approach by democratizing access to advanced prototyping technologies. By supporting accurate, repeatable fabrication during early-stage design and development, these IDEA labs help students across multiple engineering disciplines achieve state-of-the-art outcomes and better prepare for professional engineering challenges.

| 💭 Watch our video on student trainingat Pearl Academy, Noida, where students work on CO2 laser cutting machines supplied by Prakash Laser. |

Contact Us

Frequently Asked Questions

Q1. What materials are safe to use in the CO2 laser cutter?

Ans1. CO2 lasers cutting machines are incredibly versatile for non-metals. You can safely cut and engrave acrylic, wood (MDF, Plywood), leather, fabric, paper, cardboard, and rubber. However, you should never cut PVC, Vinyl, or Polycarbonate, as they release corrosive chlorine gas that is toxic to humans and damaging to the machine’s optics.

Q2. How difficult is it to maintain the machine in a college lab?

Ans2. Maintenance is straightforward but essential. Daily tasks include cleaning the focus lens and mirrors with alcohol to prevent dust buildup. Weekly, the water chiller levels should be checked to ensure the laser tube stays cool. Prakash Laser provides a detailed maintenance schedule and training to lab assistants to make this easy.

Q3. How can different departments use the CO2 Laser in a single IDEA Lab?

Ans3. IDEA Labs are designed as interdisciplinary hubs.

Fashion Tech: For fabric engraving and pattern cutting.

Mechanical/Civil: For structural models, gears, and topographic maps.

Electronics: For custom PCB housings and control panels.

Architecture/Design: For intricate scale models and stencils.

Q4. Is the Prakash Laser machine compliant with AICTE technical specifications?

Ans4. Yes. AICTE guidelines typically require industrial-grade CO2 lasers with a minimum bed size (often 600x900mm or 1300x2500mm) and power ranges between 80W to 150W. Our machines meet or exceed these specifications, featuring high-precision LM guides and the required safety interlocks essential for educational institutional tenders.