Medium-Density Fiberboard (MDF) has become a go-to material for creating 3D layered designs and intricate cutouts. Its uniform structure makes it ideal for precise work, and when paired with CO2 Laser Cutter, the results can be exceptionally clean and professional.

But here’s the real question: what makes a CO2 Laser Cutter for MDF the right choice? How do you find the best machine for 3D layering in India? And which supplier can you rely on for quality and support? This guide will walk you through the answers one by one.

Table Of Contents:

- What Is A CO2 Laser Cutter?

- Why Choose CO2 Laser Cutters 3D Layered MDF Cutouts?

- Key Measures To Master 3D Layering With A CO2 Laser Cutter

- Which Is CO2 Laser Cutter The Best In The Market? Meet Prakash Laser!

- Wrapping Up!

What Is A CO2 Laser Cutter?

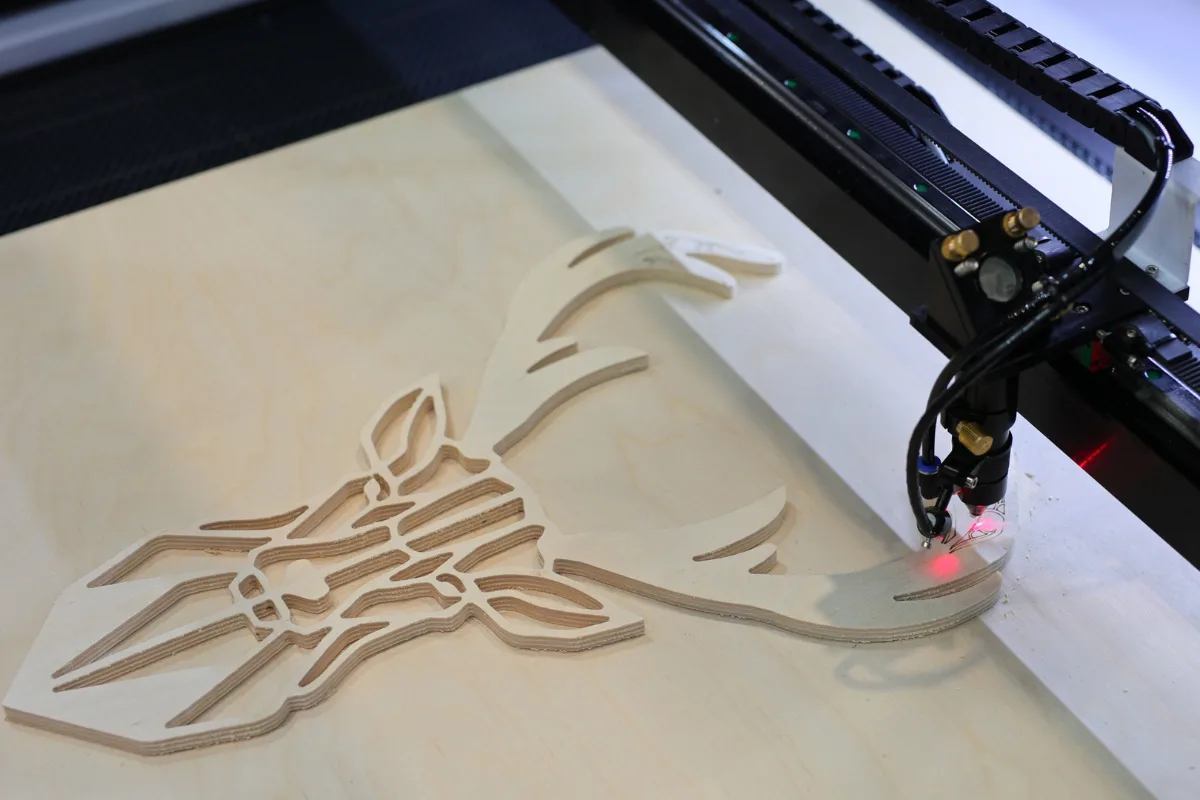

A CO2 Laser Cutter is a powerful machine designed to cut non-metal materials with precision and ease. Operating at a wavelength of 10,600 nm, which is readily absorbed by materials like wood and cardboard, it has become the go-to choice for laser cutting MDF.

This MDF Laser Cutter can cut up to 15–20 mm thick sheets in a single pass, in various sizes at high power. It also encourages innovation, allowing you to create smooth, detailed, and premium-quality products with perfection.

Why Choose CO2 Laser Cutters 3D Layered MDF Cutouts?

CO2 Laser Cutters deliver clean, accurate cuts every time. So, if you’re searching the market for a laser cutter for MDF, this should be your top choice, especially if your focus is on 3D layering. Now, are you curious to find out if there’s more to it? Let’s get down to discussing the details:

- This machine delivers sharp, smooth cuts with precise depth control, making it perfect for curved, layered, or intricate designs that bring your 3D MDF projects to life.

- With the right calibration, adjusting speed, power, focus, and using air assist, the machine prevents burning or charring, giving you a clean finish every time.

- It’s also cost-effective and time-saving, making it an excellent choice for entry-level businesses entering the world of 3D.

- Plus, among many laser cutting machines in the market, this one is simple to operate and easy to maintain.

Key Measures To Master 3D Layering With A CO2 Laser Cutter

Here are some key factors to keep in mind when using a CO2 Laser Cutter for MDF:

- Make sure you’re using appropriate, uncoated, laser-compatible MDF that cuts easily and supports high-quality, detailed, and intricate work.

- Always do a test run on a scrap piece of MDF before starting your final project. This helps you calibrate your laser settings for a clean cut while preventing charring or burning.

- Break designs into 2D layers, label them, and stack to build depth for a 3D effect. For example, check out this DIY soldering station built with MDF, a great example of how layered MDF can be applied in practical projects.

- To ensure your material remains stable throughout the process, cut smaller designs first and then move on to larger cuts.

- And lastly, always stay with your machine while the process is ongoing. Monitor if it’s running smoothly and there are no signs of fire or excessive charring.

Which Is CO2 Laser Cutter The Best In The Market? Meet Prakash Laser!

Proudly made in India with years of proven engineering, Prakash Laser delivers reliability and real value for your business through its CO2 Laser Cutting Machine. Built to last and easy to operate, the machine ensures high performance without stretching your budget. And if 3D layering is your focus, our machine offers customizable features that make the entire process faster, more precise, and highly innovative.

Still wondering if this is all true? Then see how our CO2 Laser Cutting Machine helps cut 3D MDF decorative: https://www.youtube.com/watch?v=YF0UF_mQ3JY. This Laser Cutter for MDF is simple and smooth, just how it should be. Isn’t it? Absolutely!

Wrapping Up!

Finally, we’d say that mastering 3D layered MDF cutouts with a CO2 Laser Cutting Machine is made simple with Prakash Lasers. And we’re not just selling machines, we’re making the journey of a 3D design to finished product straightforward, fast, and accessible. So, don’t forget to check us out!