Laser cutting machines are widely used for precise, high-temperature cutting in workshops, labs, and industrial environments. While these machines are built for accuracy and efficiency, they rely heavily on powerful laser beams, extreme heat, and electrical systems that require careful handling at all times. Therefore, following proper safety precautions for laser cutter operation isn’t optional, but essential.

Since fire hazards, eye exposure, fumes, and mechanical risks are all part of the laser cutting process, the safety steps cannot be overlooked. So, we’ll list the safety precautions below, focusing specifically on laser cutting machines, to help operators avoid the risks they face during everyday use. Read until the end.

Table Of Contents

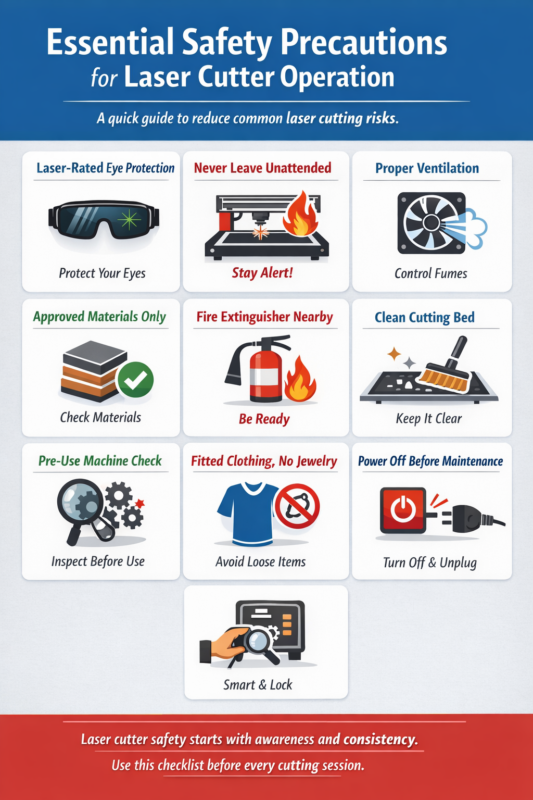

Top 10 Essential Safety Precautions For Smooth Laser Cutter Operation

1. Wear Laser-Rated Eye Protection

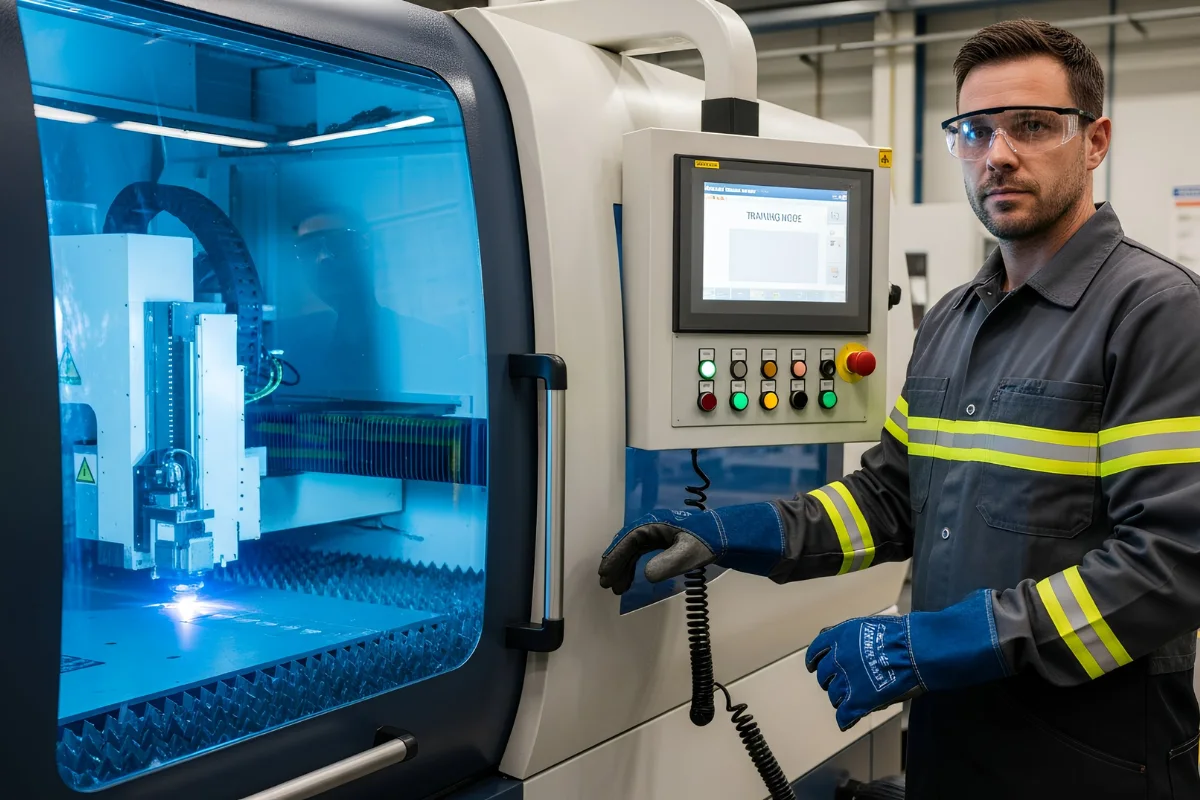

One of the first safety precautions when using a laser cutter machine is always wear laser safety goggles rated for the machine’s wavelength. It will protect the operator’s eyes from direct or reflected laser exposure.

2. Never Leave The Machine Unattended

Laser cutting generates intense heat and sparks during operation, posing a constant fire risk. Staying present allows immediate action if a flare-up, material shift, or unexpected issue occurs.

3. Ensure Proper Ventilation and Fume Extraction

Laser cutting produces smoke and airborne particles, which is why proper ventilation is a key part of laser cutter safety precautions. So, ensure proper ventilation and exhaust, and never let cutting gases return directly to the workspace.

4. Use Only Approved And Compatible Materials

Some materials can release toxic or corrosive fumes when cut. So it’s essential always to confirm material compatibility and review the safety data sheet before starting the laser cutting job.

5. Keep A Fire Extinguisher Within Reach

Keep a CO₂ or dry chemical fire extinguisher within reach of the workstation, ensure it’s within its service date, and know how to use it in case of flare-ups.

6. Maintain A Clean Cutting Area

Keep the cutting bed clear of leftover debris and scrap material, as buildup can increase fire risk and interfere with clean, consistent cutting.

7. Check Machine Components Before Starting

Before starting, take a moment to check the lenses, mirrors, belts, and wiring for dust, wear, or misalignment to avoid unexpected issues during laser cutting operations.

8. Avoid Loose Clothing and Accessories

Wear fitted clothing and remove any jewelry as part of basic safety gears when using laser cutter, helping prevent accidental contact with moving parts or hot surfaces.

9. Follow Manufacturer Guidelines and Settings

Stick to the power, speed, and material settings recommended by the manufacturer, as following these safety precautions for laser cutter operation helps keep cutting controlled, safe, and predictable.

10. Disconnect Power Before Maintenance Or Cleaning

And lastly, before cleaning or making any adjustments, always turn off and unplug the machine. This is one of the most critical laser cutter safety considerations to prevent any accidental startup.

By following the above-mentioned laser cutter safety rules, you can reduce common risks and establish a clear foundation for safe machine operation.

Additional Laser Cutter Safety Tip:

Never Bypass Safety Interlocks

Modern machines, including CO2 Laser Cutting Machine and Fiber Laser Cutting Machine, are built with safety interlocks that automatically shut off the laser when the lid or enclosure is opened. These features are designed to protect the operator during the workflow. Disabling them can expose the operator to intense laser radiation and create serious safety risks. Keeping all safety interlocks intact is a simple but critical part of safe laser cutter operation.

Read more: How To Choose The Right Laser Cutting Machine? Buying Guides.

Final Thoughts On How To Use A Laser Cutter Safely

Following proper safety precautions for laser cutter use isn’t just about ticking boxes or following a checklist. It’s about being present while it’s running and staying aware of what’s happening around the machine. When safety becomes second nature, laser cutting feels more controlled and less rushed. Small habits, like paying attention, maintaining the equipment, and taking a moment before each session, lead to the best results and an optimal work environment for everyone.

Read more: 4 Popular Types of Laser Cutting Machines You Should Know.

Frequently Asked Questions

1. Are desktop laser cutters safer than industrial laser cutters?

Desktop laser cutters may feel less intimidating due to their size, but they still pose safety risks if handled carelessly. Therefore, proper supervision, ventilation, and safe operating habits are necessary for both desktop and industrial machines.

2. How often should laser cutter safety checks be done?

Laser cutter safety checks should be performed before every cutting session to ensure the machine is set up correctly and operating as expected. Regular checks help prevent avoidable issues during operation.

3. Do different types of laser cutters require different safety precautions?

Yes, safety precautions can vary depending on the laser type, such as a CO2 Laser Cutter or a Fiber Laser Cutter. Each machine has unique operating characteristics, making it important to follow safety guidelines specific to the cutter being used.