A laser cutter with pass through design lets the material move straight through the machine, eliminates constant interruptions, and makes larger projects feel far more manageable. But that ease wasn’t always part of the process. Anyone who has tried cutting long sheets on a standard laser machine would know how challenging it can be. You line things up, start cutting, stop midway, adjust again, and repeat. It slows down the whole process. But those days are gone, as a laser cutter with a pass through design is here to quietly change the game.

In this article, we’ll be discussing how a CO2 Laser Cutting Machine with a pass-through door design works. From what makes it practical to the situations where it actually makes a noticeable difference, this covers everything you need to know. Let’s get started.

Table Of Contents

What Is A CO2 Laser Cutter With Pass Through Door Design?

A CO2 laser cutter with a pass through door design is perfect when your material is longer than the cutting bed. Instead of squeezing projects into a fixed space, the machine lets the material move through smoothly and naturally.

Here’s how a laser cutter with pass through helps:

- Openings at the front and back let material slide through easily

- Keeps long sheets aligned while cutting

- Eliminates the need to stop and break projects into sections

The key takeaway:

The material moves through the machine efficiently. This small design change makes continuous cutting simpler and more manageable, especially when working with oversized pieces or longer runs.

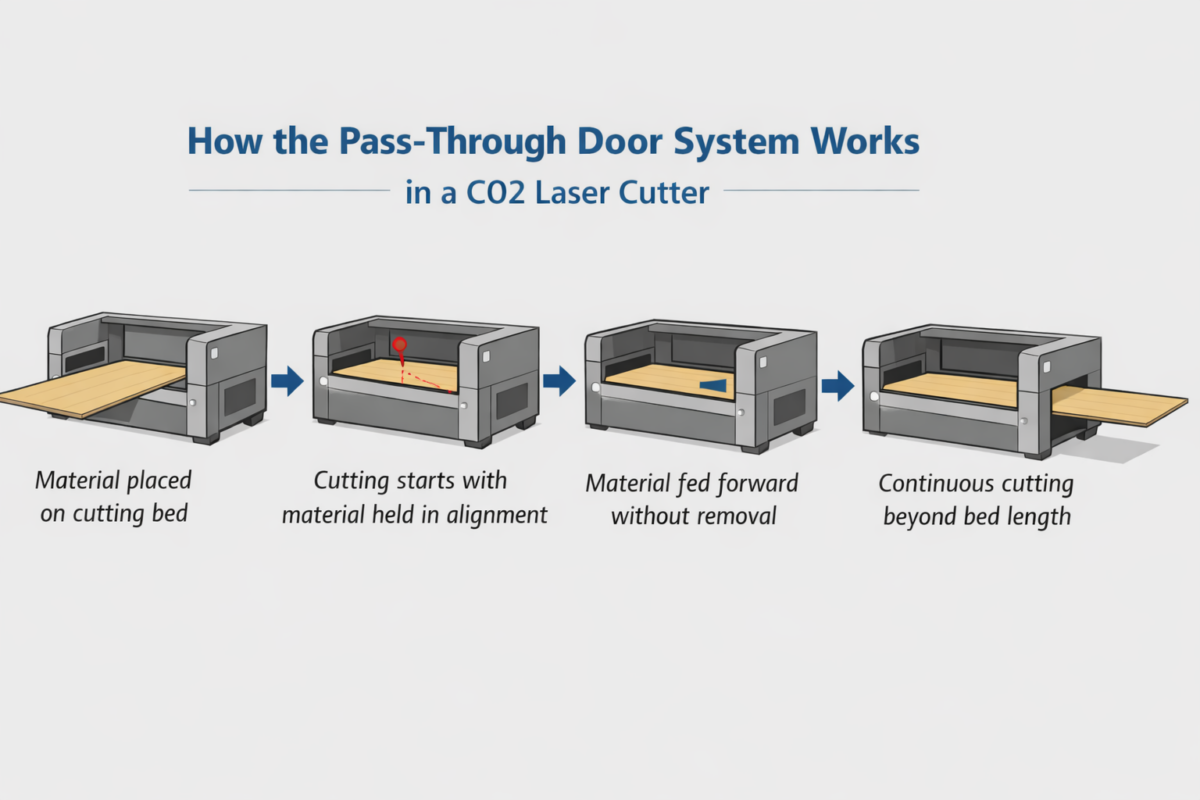

How The Pass-Through Door System Works

The pass-through door system allows you to place the material on the cutting bed, close the doors, and cut as you normally would. When the cut reaches the end of the bed, you simply feed the material forward instead of pulling it out and starting over.

What this improves:

- Reduces stopping, lifting, and readjusting

- Allows steady progress on longer sheets

Common Applications Of A CO2 Laser Cutter With Pass Through Door Design

Signage And Displays

Pass-through laser cutting door design is commonly used for cutting acrylic sheets, especially for signs, display panels, and other branding elements where longer, cleaner cuts matter.

- It handles long acrylic sheets without trimming them down first.

- Works exceptionally well for repeated lettering, panels, and layout work.

Wood, Furniture, And Panels

For laser cutting wood panels, a pass through laser cutter makes longer cuts easier to handle.

- The machine cuts down the need to split large wood panels into smaller sections.

- Works well for furniture parts, wall panels, and decorative elements.

Textiles, Flexible Materials

In textile laser cutting, continuous material movement makes a real difference. Here’s where it really pays off.

- Let’s you feed material forward gradually without throwing off alignment.

- Lastly, it’s ideal for patterns, trims, and repeat designs on various fabrics.

Read more: 4 Popular Types of Laser Cutting Machines You Should Know.

Key Features Of A Pass-Through CO2 Laser Cutter

- Front and rear access doors: This feature allows you to run your operation without interruption

- Extended material support: Enables cutting beyond the physical bed length while keeping the alignment intact

- Controlled material movement: Lets you feed material forward gradually instead of removing and resetting it

- Sealed door design: Keeps the cutting area contained while still letting material move smoothly through the machine

- Flexible for different material types: Works with rigid sheets, panels, and roll-based materials

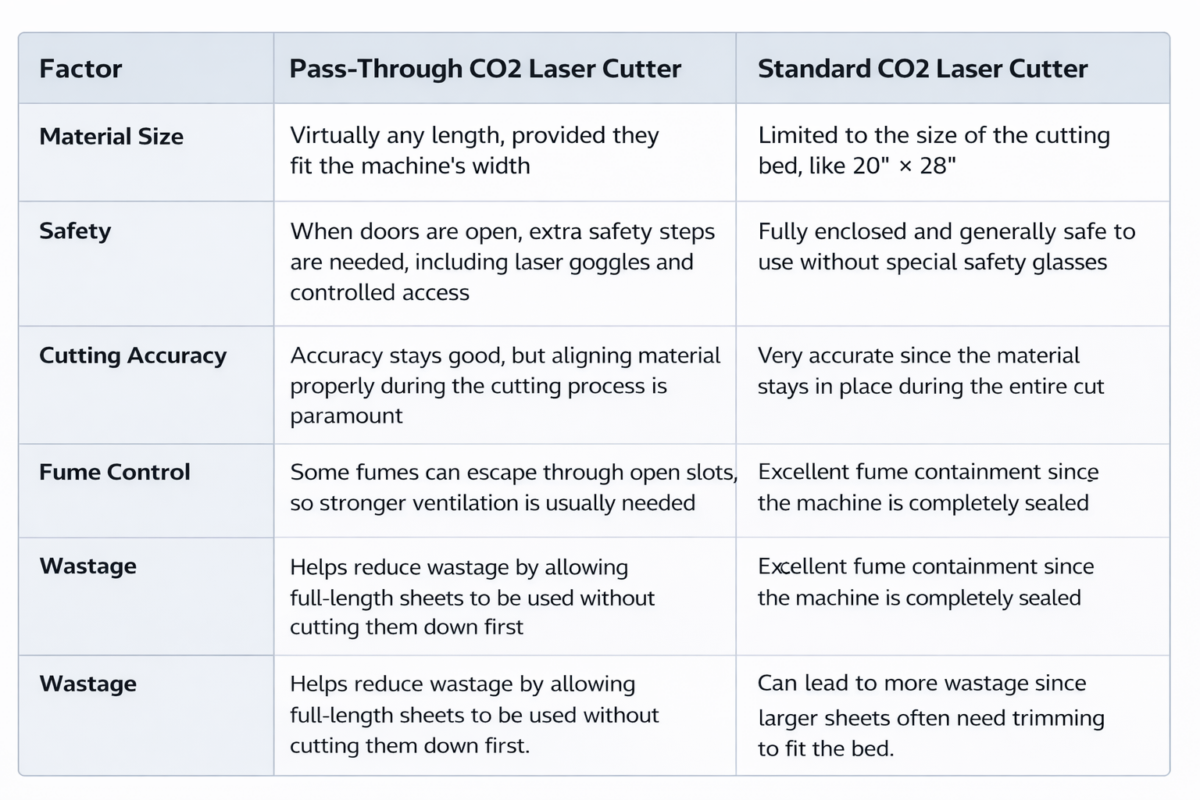

Pass-Through Door vs Standard CO2 Laser Cutters

Pass-through door design and standard CO2 laser cutters work a bit differently, and understanding that difference helps make sense of how each setup is used. Take a look:

Choosing The One That Truly Fits Your Workflow

Every workspace runs differently, so understanding what your business actually needs should come before you decide to invest in either of the two pieces of equipment. However, a laser cutter with a pass through design is a smart choice when you know your material size and requirements. It results in a smooth workflow where consistent results matter. With this, you can expect long-term efficiency without adding unnecessary complexity.

See our machines in action on our YouTube channel.

Frequently Asked Questions

1. Does a laser cutter with pass through door design increase the cutting size?

A laser cutter with a pass through door design increases the usable cutting length because material can feed through the machine continuously. However, it does not increase the cutting width, as it is still limited to the size of the machine’s bed.

2. Is a pass-through laser cutter different from a standard CO2 laser cutter?

Yes, the main difference is how the material is handled. Pass-through designs let longer materials move through the machine instead of being limited by the bed length.

3. Are pass-through laser cutters harder to operate?

No, they operate similarly to standard CO2 laser cutters, with the added ability to feed material forward during longer cutting operations.

4. Do pass-through doors affect cutting accuracy?

When material is correctly aligned, cutting accuracy remains consistent, even during longer or repeated cuts.

5. Do laser cutters with pass through door design have any limits?

Yes. They allow material to move through lengthwise, but the bed size still limits the cutting width. You’ll also need enough space in front and behind the machine for smooth feeding. For smaller projects, a standard CO2 laser cutter can do the job just fine.