Table Of Contents:

- All You Need To Know About CO2 Laser Tubes

- So, Why Is Water Temperature An Important Factor For CO2 Laser Tube Lifespan?

- What Are The Tips To Maintain The Right Water Temperature?

- So, How Long Will A CO2 Laser Tube Last?

- Final Words!

All You Need To Know About CO2 Laser Tubes!

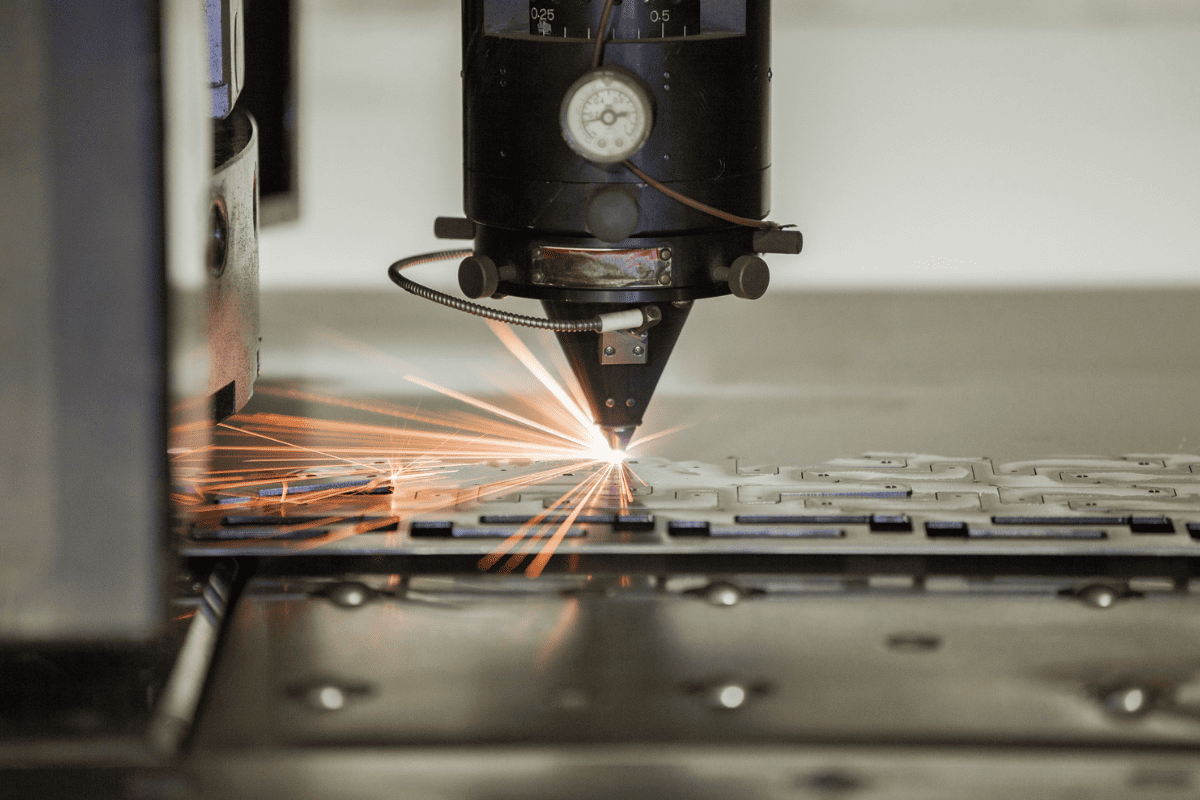

A CO2 Laser Tube is the main part of a laser cutting machine. It works by exciting a mix of CO2 gas inside a sealed glass tube to create a powerful, focused laser beam, typically at 10.6 µm wavelength. This beam is then guided through mirrors and lenses to cut or engrave materials with great precision. CO2 laser tubes are widely used because they can process materials like wood, acrylic, leather, fabric, and even glass smoothly and accurately. Wondering what’s more to it? Take a look:

Features Of A Glass CO2 Laser Tube:

- They use direct current (DC) excitation.

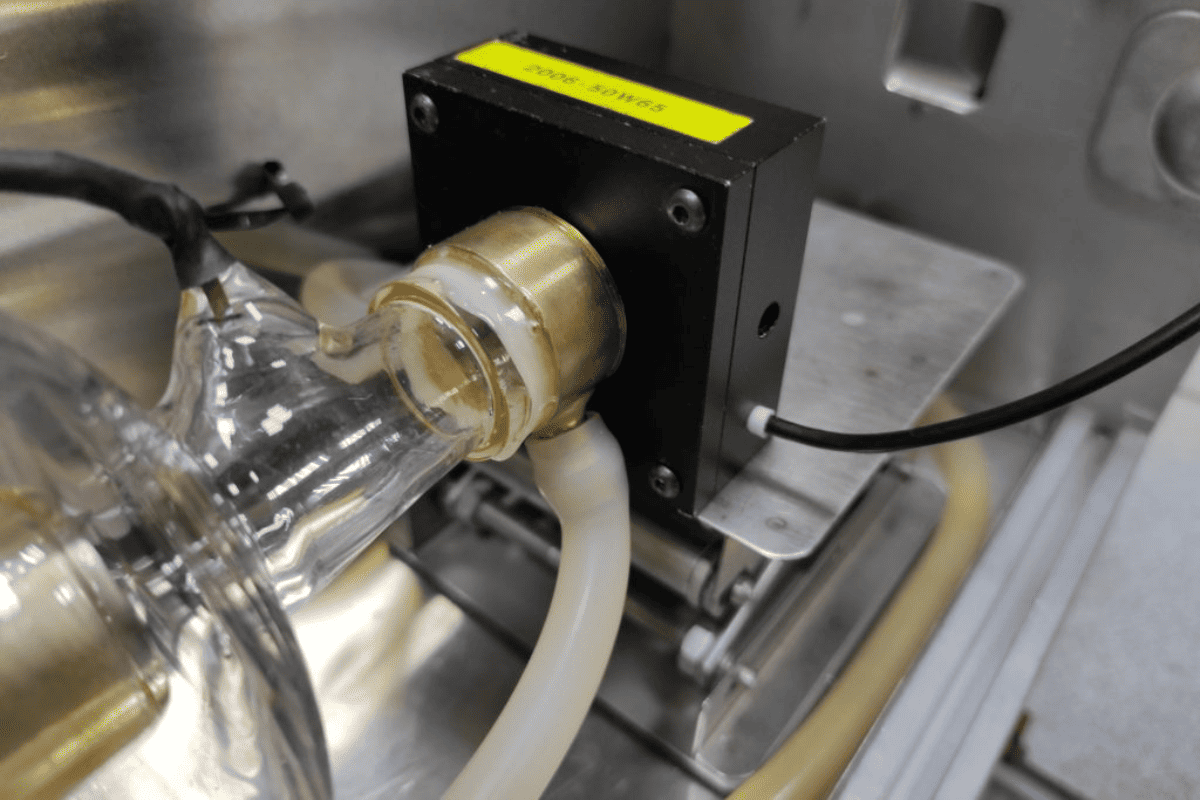

- These tubes require a water cooling system to maintain a stable temperature and operation.

- Their lifespan ranges from 1,000 to 10,000 hours, depending on the quality and usage.

- They produce a multi-mode laser beam, resulting in a larger spot size.

- Since they come with the advantage of a lower initial cost, they are perfect for beginners, hobbyists, and small workshop owners.

So, Why Is Water Temperature An Important Factor For CO2 Laser Tube Lifespan?

It’s simple. To understand the concept of CO2 laser tube lifespan, it is essential to maintain the correct water temperature, ideally between 15°C and 25 °C. Still wondering why? Let us explain.

The laser tube generates heat during operation, and if the cooling water is too warm, the CO2 gas inside the tube can lose stability, potentially reducing the laser’s power output. On the other hand, if the water is too cold, it can cause condensation that may damage the tube’s electrodes.

And understandably, whatever project you’re working on, you wouldn’t want that to happen, right? That’s why maintaining the correct water temperature is key to extending your laser tube’s lifespan.

What Are The Tips To Maintain The Right Water Temperature?

Here are some easy ways to maintain the correct water temperature, which may help extend your CO2 laser tube’s lifespan:

- Check the cooling unit for any blockages or leaks, and make sure it’s free of debris to prevent overheating. Taking care of such small yet practical steps will help ensure the tube operates seamlessly and efficiently.

- Regular tap water can contain particles that build up inside the cooling system. Therefore, using distilled or deionized water is a much better option.

- Monitor for water leaks at regular intervals and clean the chiller regularly to prevent issues.

- Control the water temperature and avoid high or fluctuating temperatures at all costs.

So, How Long Will A CO2 Laser Tube Last?

Once you understand how to maintain the correct water temperature, you’ll also need to control other factors that can influence the CO2 laser tube lifespan. Take a look:

- Ensure you’re optimizing power and speed settings for different materials, such as wood or acrylic. Remember to test and tune before going in for final production.

- If you run your machine at full power for long periods, you’re putting the laser tube at a higher risk. Avoid at all costs.

- Recognize the right time to replace or upgrade parts to extend the life of your CO2 laser tube. If there’s reduced output, overheating, or visible damage, change it immediately.

- Storage matters, so avoid humidity and direct sunlight to prevent unnecessary damage.

Final Words!

As one of the most essential CO2 laser accessories, CO2 laser tubes require some maintenance, especially regarding water temperature. However, it’s all worth it. The results you can achieve with them are truly remarkable. So, make sure you follow the tips mentioned above to extend your ‘CO2 laser tube lifespan!’

Additionally, remember to purchase them from a reputable vendor. And it goes without saying, Prakash Laser is the name you can trust. A pioneer in Laser Spare Parts, Prakash Laser offers state-of-the-art laser technologies built to global precision standards and backed by advanced R&D. That’s right, it’s truly a place where technology meets innovation.