Are you in the business of creating goodies with fabrics? Think cozy cushion covers, chic curtains, trendy clothing, fabric toys, and stylish labels? Then here’s something that might just change the way you work: a CO2 Laser Cutting Machine for Roll Feeder. This powerful combo isn’t just about speed; it’s about precision, perfection, and pure convenience. Imagine cutting intricate designs with smooth edges and repeating patterns, without hassle or breaking any thread.

Wondering how it all works? Get ready, as we’re about to take you on a quick journey through the world of CO2 laser cutting with roll feeders and why it’s the ‘IT’ machine for your design business.

Table Of Contents:

- What Are CO2 Laser Cutting Machines With A Roll Feeder?

- What are The Key Functions Of A Roll Feeder?

- What Are The Industries Where A Roll Feeder Shines?

- Final Words!

What Are CO2 Laser Cutting Machines With A Roll Feeder?

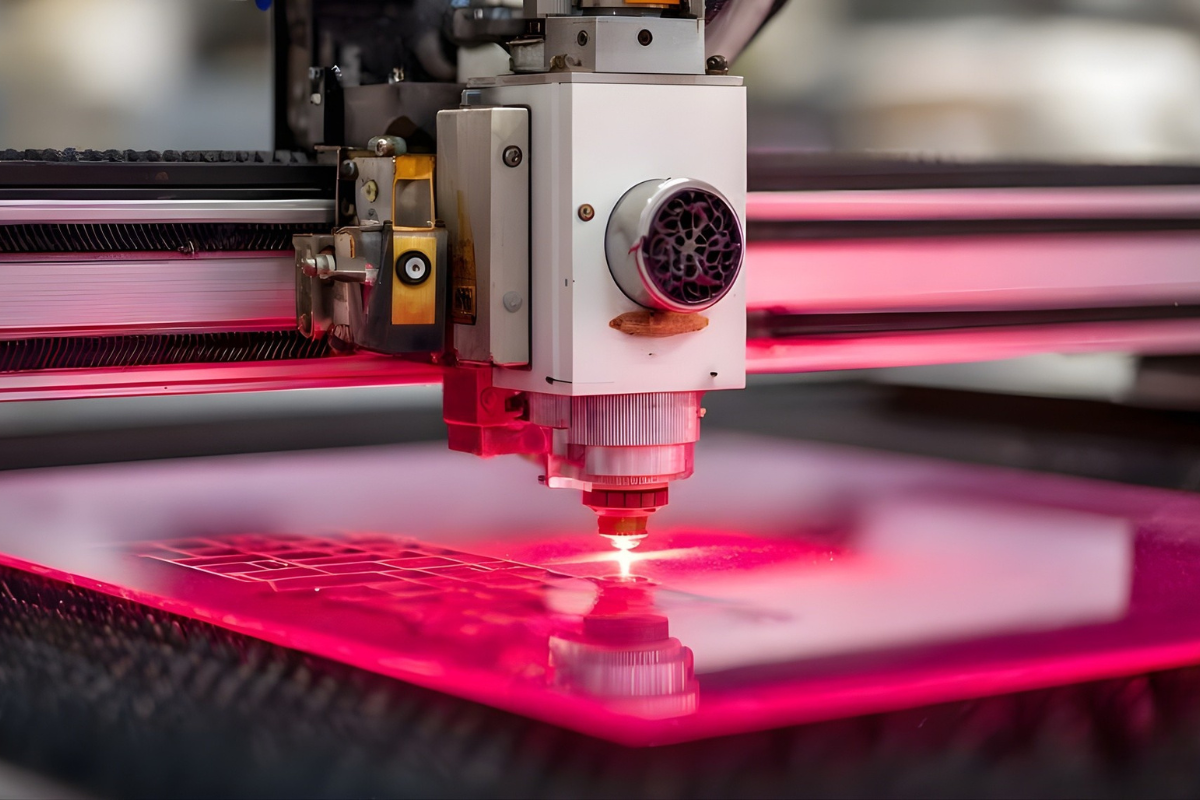

A CO2 Laser Cutting Machine with a Roll Feeder is an automated system designed to efficiently cut long rolls of flexible materials such as fabric, leather, and textiles. The roll feeder continuously feeds the material onto a conveyor or cutting bed while the laser performs precise cuts. This enables uninterrupted, high-precision, high-volume production with minimal manual labor.

Note: Book a demo of our CO2 Laser Cutting Machine, and let our experts guide you on how it can benefit your business.

What Are The Key Functions Of A Roll Feeder?

Here’s how a roll feeder works:

- Automatic feeding: A roll feeder can automatically pull fabric material from a roll and move it forward onto the cutting area.

- Non-stop operations: It is designed for continuous and synchronized cutting operations, enhancing work efficiency and reducing labor costs.

- Precision and accuracy: Typically built with components that support precision cutting, such as linear guide rails and precision gears, this system ensures every cut is achieved at high speed with accuracy and precision.

- Automated collection: This technology includes an auto-collecting device that automatically gathers finished pieces as they’re cut. It eliminates the need for manual collection, reduces labor costs, and facilitates large-scale cutting more quickly and easily.

- A versatile technology: It can handle a wide range of non-metal materials, such as textiles, leather, and more.

- Smart material usage: Since the roll feeder keeps the fabric aligned during feeding, it may help reduce wastage caused by slippage, wrinkles, or uneven cuts — especially in long-run production.

What Are The Industries Where A Roll Feeder Shines?

Industries that are suitable for a ‘CO2 Laser Cutting Machine for roll feeder’ operation:

- Fashion: It’s the perfect choice for cutting intricate patterns for clothing, footwear, and fashion accessories, ensuring manufacturers stay ahead of the changing trends in the garment and apparel industry.

- Furniture: Processing large rolls of upholstery for furniture is a cakewalk for a roll feeder. It ensures that the large-scale demands of the furniture industry are met with precision, accuracy, and speed.

- Automotive: Whether it’s car seat covers or floor mats, with this technology, premium-quality results with smooth edges, intricate detailing, and a clean finish are achievable, with no hassle or compromise.

- Signage and Advertising: A CO2 Laser Cutting Machine with a Roll Feeder helps produce clean edges, intricate lettering, and precise shapes without fraying or distortion, ensuring every sign looks sharp and professional.

Final Words!

Ultimately, we believe that if you work in the fabric industry and aim to maximize productivity with reduced effort, lower costs, and minimal labor, a CO2 Laser Cutting Machine for Roll Feeder is your ideal solution. It enhances production speed, optimizes material usage, ensures precise results, and reduces manual dependency, making your operations smoother, faster, and more efficient.

Since feeding becomes automated, teams can focus on other value-driven tasks like stitching, detailing, or finishing—areas where human skill truly matters.

So, go ahead, bring this innovative solution to your business today!