High Precision Laser Cutting Machine For Leather

The Leather Laser Cutting Machine is designed to deliver high-precision cuts and engravings on natural and synthetic leather materials. Using CO2 laser technology, these systems offer non-contact processing that ensures clean edges, intricate detailing, and minimal material waste. The leather cutting laser machine is ideal for creating patterns and logos without burning or unraveling the material’s layers.

Commonly used in industries such as footwear, fashion accessories, upholstery, and automotive interiors, the laser cutting machine for leather enables high-speed, repeatable cutting with precise accuracy on a wide range of leather types.

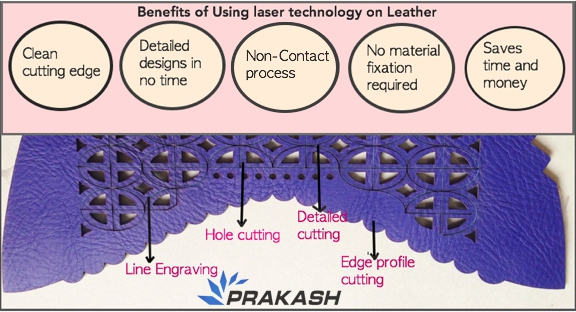

What Are The Benefits Of Using A Leather Laser Cutting Machine?

The Leather Laser Cutting Machine offers multiple advantages, making it suitable for a wide range of industrial applications. Here are some of the key benefits that highlight their efficiency and versatility:

- High-Precision Cuts: Ideal for both natural and synthetic leathers with accurate detailing.

- Contactless Process: Prevents stretching, warping, or tearing of delicate materials.

- Sealed, Burn-Free Edges: CO2 lasers produce clean, fray-resistant edges on suede, PU leather, and more.

- Handles Complex Designs: Perfect for intricate patterns, perforations, and branding details.

- Fast & Scalable: Speeds up production while ensuring consistent quality.

Benefits of Using Laser Technology on Leather

Top Industries Using Leather Laser Cutting Services

1. Footwear Manufacturers

Used to cut leather uppers, soles, and detailing components with consistency, helping achieve complex shapes and high-volume production without manual trimming.

2. Fashion and Apparel Brands

Enables precise cutting and engraving of leather jackets, belts, patches, and trims—supporting both mass production and seasonal customization.

3. Automotive Upholstery and Interior Units

The leather laser cutting machine is ideal for processing carpets, leather seat covers, dashboards, and trims where precision, repeatability, and design uniformity are critical.

4. Furniture and Upholstery Workshops

Helps businesses to create shaped leather panels, stitched accents, and decorative overlays for luxury chairs, sofas, and headboards.

5. Leather Goods and Bag Manufacturers

Help manufacturers achieve high-precision crafting of wallets, handbags, luggage tags, and strap systems—especially useful for delicate pattern detailing.

6. Corporate Gifting

The leather laser cutting machine is used for custom engraving of company logos, names, or messages on gift items like diaries, folders, cardholders, and branded kits.

7. Craft Studios and Independent Artisans

Popular among small businesses for personalized items like bookmarks, coasters, watch bands, and journal covers with intricate, high-quality engraving.

On What Types Of Leathers Do The Leather Laser Cutting Machines Work On?

This Laser Leather Cutting Machine enables makers to process all kinds of leather, including synthetic leather, natural leather, napped leather, suede leather, and cow leather. Making them super practical and versatile, and helping manufacturers save more in the cutting process.

From precise pattern cutting to high-speed production, Leather Laser Cutting Machine offers a reliable solution for manufacturers working with both natural and synthetic materials. Whether you’re producing footwear, automotive interiors, or custom leather accessories, this technology supports accuracy, consistency, and flexibility.

Achieve High Quality With Leather Laser Cutting Machines

Deliver clean cuts, intricate patterns, and flawless edges every time with Prakash Lasers’ advanced CO2 Leather Laser Cutting Machine. Built for precision and durability, these machines are built to handle all types of leather with ease, supporting both detailed work and high-volume production.

Notably, P-6040 and P-960 are our most popular Leather cutting laser machines. We’re receiving positive reviews from our buyers in the leather industry for the high precision and low operational cost of these machines, making them the most acceptable models. They feature a single head and are equipped with all the basic functionalities of laser cutting and engraving machines, allowing them to be used on multiple surfaces.

Whether you’re manufacturing footwear, auto interiors, or custom accessories, our technology ensures speed, accuracy, and material efficiency. Choose Prakash Laser to elevate your leather processing and bring unmatched speed to your production floor. Connect with us today to discover the right solution for your business.