Just starting your business and wondering how to laser engrave Aluminum, or what it takes to make your custom Aluminum products really stand out? Tired of the old-school methods that take forever and don’t give you that perfect finish? Don’t worry, you’re in luck. Aluminum laser engraving is faster, long-lasting, and far more precise, making your life a whole lot easier. Let’s get into everything you need to know to take your engraving game to the next level.

What Is Aluminum Laser Engraving?

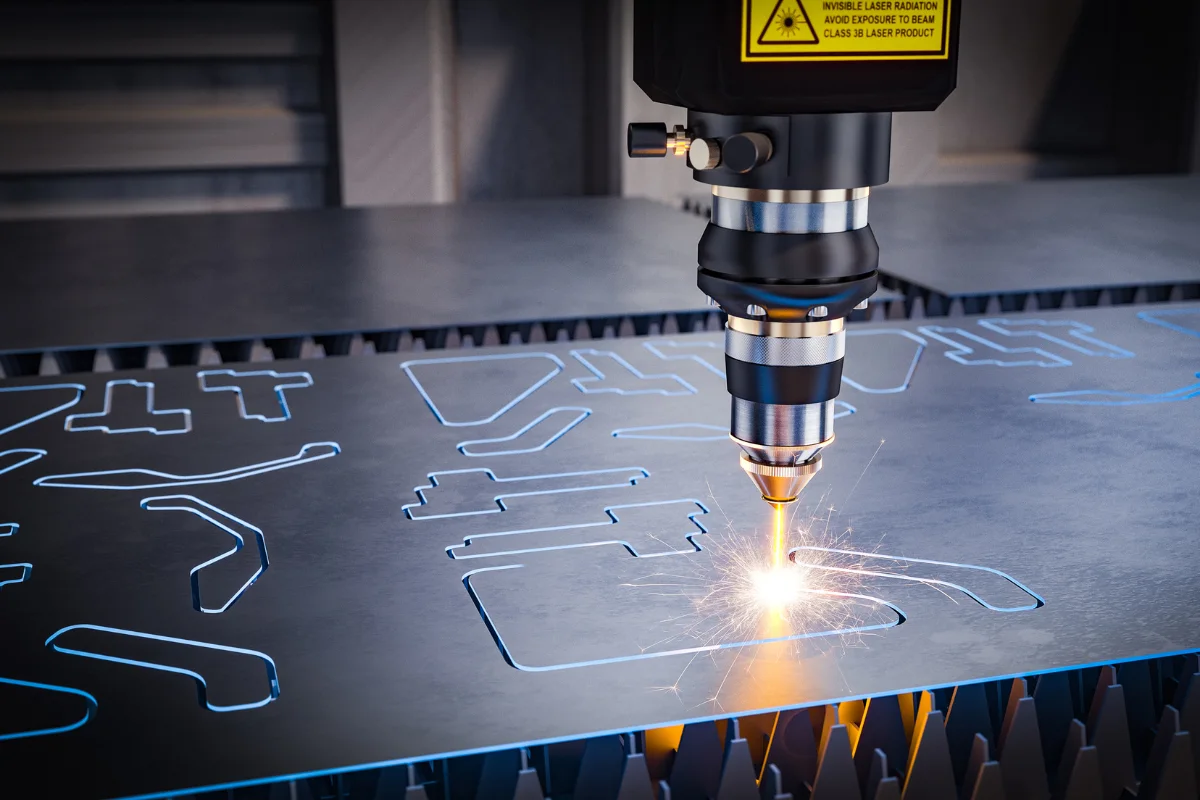

Aluminum laser engraving is a process where a high-powered, focused beam of light vaporizes the surface layer of Aluminum. This creates a clean, permanent mark without any physical contact. The technology allows for highly detailed and durable engravings, perfect for making products traceable, giving them a branded finish, or adding a personal touch. Wondering how it works?

How Laser Engraving Aluminum Works?

The laser engraver directs a powerful beam of light onto the Aluminum surface, heating it so fast that it turns directly from solid to gas. The machine’s software controls the laser’s speed and strength, removing a thin layer of metal with great precision to create your chosen design or text. It is widely used in industries such as automotive and electronics for barcoding and serial identification.

What Are The Benefits Of Laser Engraving Aluminum?

Here are some of the benefits you can enjoy when engraving on Aluminum with a Metal Laser Engraving Machine:

- Affordability: This machine easily engraves a variety of metals, including Aluminum, delivering high-contrast and precise results at highly budget-friendly prices.

- Permanence and durability: The laser engraver for metal creates marks on Aluminum that are resistant to harsh conditions. Say no to wear, scratches, or corrosion.

- Increased traceability: Durable marks, such as serial numbers, barcodes, or QR codes, are crucial for tracing products, and Aluminum laser engraving makes this possible.

- Speedy processing: Once the design for laser engraving Aluminum is programmed, the process becomes fast and automated, offering efficient production for both high-volume and small projects.

- Eco-Friendly and Reduced Wastage: Laser engraving creates minimal waste, and no harmful chemicals, acids, or inks are required, making it a cleaner and more eco-friendly process.

- Customization: It works wonderfully on Aluminum products meant for decorative pieces, personalized gifts, and more.

What Types Of Aluminum Are Used For Laser Engraving In 2025?

Here are the Aluminum that are compatible with Metal Laser Marking Machines:

Bare Aluminum

A raw sheet of Aluminum with no special coating is great for precise engraving, though the contrast may be subtle compared to anodized Aluminum.

Anodized Aluminum

Extremely versatile for engraving, anodized Aluminum has a durable, permanent oxide layer that can be dyed in a variety of colors. When the laser strikes the surface, it removes the colored anodized layer, revealing the silver or white metal underneath, and creates a high-contrast mark.

This makes it ideal for text, logos, barcodes, and serial numbers, offering excellent visibility and durability.

Powder-Coated Aluminum

This type of Aluminum has a durable layer of paint or powder coating for protection and decoration. When laser-engraved, the top layer is removed to reveal the bare metal underneath, creating a clear, high-contrast mark.

Aluminum Alloys

Aluminum is often combined with other metals to enhance its strength and resistance to corrosion. Laser engraving works the same on these alloys as on pure Aluminum, removing material to create a precise, durable, permanent mark.

Common Mistakes To Avoid While Laser Engraving Aluminum

Here are a few pointers to keep in mind while engraving on Aluminum:

- Choose a laser type with a wavelength that metals can absorb, such as a fiber laser, to achieve deep and precise engraving results.

- Don’t assume one setting works for all types of Aluminum; different alloys and coatings react differently. Calibrate your machine correctly and adjust the power, speed, and focal length as per your needs.

- Clean the Aluminum surface thoroughly to remove oils, dirt, and other contaminants. This helps prevent uneven or poor-quality engraving.

- Manage heat properly and ensure proper ventilation to protect both the machine and the material.

Who Makes The Best Laser Engraving Machine For Metal?

So, if you’re still asking, ‘Can you laser engrave Aluminum?’ or ‘What’s the best machine for Aluminum laser engraving?’ You can stop right there. We’ve already answered the first question.

As for the second, the answer is simple: Prakash Laser, and no one else. Our Metal Laser Machine is built to global precision standards, backed by advanced R&D, and proudly manufactured in India. It performs laser engraving on metal with nothing short of perfection.

So, stop the overthinking and book a demo today. Our team of experts will help you through the process, and all you need to do is grab the opportunity to take your business to the next level.