Ever wished you could slice through plywood like a hot knife through butter, without the splinters, slow speed, or any tedious rework? That’s where the Double Head CO2 Laser comes out as a true winner for laser cutting plywood. With two laser heads working side by side, it doubles your speed and delivers precise results, all while you sit back and enjoy your cup of tea. Whether you’re running a business or aiming to set up a production target, this machine is your secret weapon, offering cleaner cuts, faster turnaround, and a finish that truly shines.

What Is A Double Head CO2 Laser Cutting Machine?

The Double Head CO2 Laser Cutting Machine is a highly efficient technology for mass production, capable of doubling output. With two heads operating simultaneously, it cuts faster and wastes less material, resulting in a lower cost per piece.

This makes it a great tool for boosting profitability, especially in businesses where laser cutting plywood is a primary focus. Wondering how it can improve plywood cutting efficiency? Let’s find out.

How A Double Head CO2 Laser Improves Plywood Cutting?

Here’s how this plywood laser cutting machine improves work efficiency and operations. Take a look:

Increases Productivity For Repeated Patterns

For jobs that require two identical pieces, a double-head laser can cut both simultaneously. It delivers twice the output of a single-head machine, making it ideal for various industries such as furniture, packaging, signage, etc., where precise, identical cuts of plywood are essential.

Reduces Waste And Increases Yield

With two heads, the machine can utilize the material more efficiently, cutting across the full width and minimizing waste. Hence, proving that this technology is more efficient and cost-effective, especially for large plywood projects.

Offers Speed And Flexibility

This Double Head advanced machine can work independently, cutting different shapes simultaneously. This feature allows you to complete more complex projects faster, as the machine is not limited to cutting identical pieces.

Minimizes Downtime

If one laser head requires maintenance, the other can continue to operate independently. This reduces downtime of the machine and ensures that the production runs smoothly without minimal interruptions or breaks.

Offers Versatility

For some applications, our double-head machine can both engrave and cut at the same time. This lets one machine handle both tasks in a single pass, offering versatility, saving time, and thereby boosting efficiency.

Double Head vs. Single Head CO2 Laser Comparison

| Factors | Double Head CO2 Laser | Single Head CO2 Laser |

|---|---|---|

| Speed on bulk projects | Higher | Standard |

| Energy efficiency | Optimized for large runs | Efficient for smaller runs |

| Operator efficiency | Designed for productivity | Easy to manage |

| Cost-effectiveness | Best for mass production | Cost-effective for varied jobs |

| Ideal application | Large-scale, repeated patterns | Flexible, diverse projects |

As you can see, both options bring value depending on your production needs. If you’re working with plywood on a larger scale, the double-head machine can save significant time and material. On the other hand, for businesses handling varied designs or smaller runs, a single head CO2 laser remains a dependable and efficient solution.

Who Makes The Best Double Head CO2 Laser? Meet Prakash Laser!

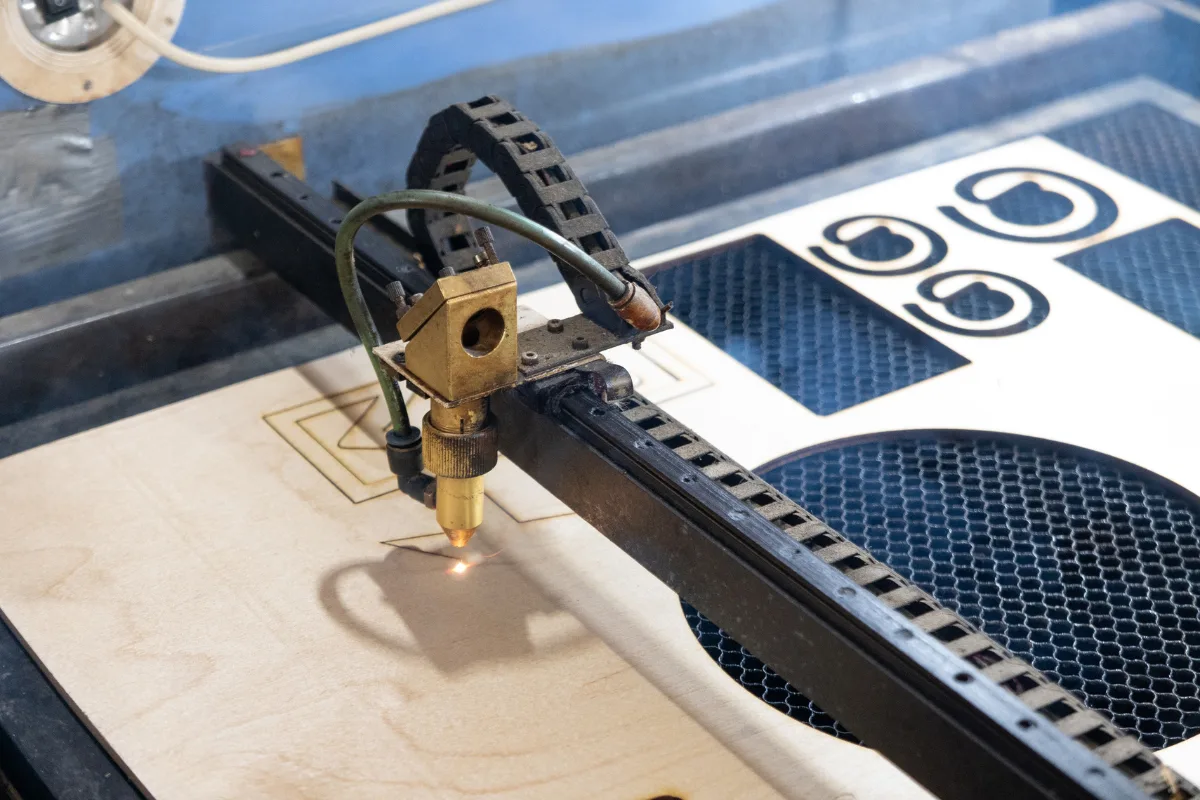

At Prakash Laser, our Double Head CO2 Laser is your perfect answer for “how to laser cut wooden sheets like a pro?” Our machine is built for speed, featuring a cutting rate of 60,000 mm/min and a laser power range of 30–150 W.

Designed for high-efficiency mass production, it comes equipped with a visible red dot pointer, an LCD panel, water protection, a honeycomb worktable, and air assist for cleaner, safer cuts.

Not only that, but this versatile machine can also handle a wide range of materials, including wood, paper, leather, textiles, acrylic, epoxy resin, wool, plastic, and even bamboo. Backed by global-standard precision and advanced R&D backing, this state-of-the-art laser cutter for plywood has changed the way it is cut across the industry.

Benefits of Choosing Us:

- At Prakash Laser, we can tailor our machine and fine-tune its design to match your unique operational requirements.

- Our machine has proven its capabilities across various clients in multiple industries and countries worldwide.

- We offer expert support at every stage of your journey, from product selection to installation, training, and beyond.

- Our machines are proudly made in India, combining advanced functionality with cost efficiency to deliver outstanding value in each one.

Final Thoughts On Laser Cutting Plywood!

So, what’s holding you back? Aren’t you ready to improve the way you’ve been laser cutting plywood? Trust us, it’s a game-changer for your business.

Don’t wait any longer. Contact us now and book a demo. With our Double Head machine, you can truly double your profits.