The automobile industry doesn’t have room for guesswork. It’s complex and demanding, especially when it comes to automobile shock absorbers. They need to be durable, precise, and efficient over the long run to ensure both quality and safety.

In this blog post, we’ll discuss how fiber laser marking has completely changed this game and why you should choose it. Read on until the end and get all the information you need on Fiber Laser Marking job work:

Table Of Contents

What Is A Fiber Laser Marking Machine?

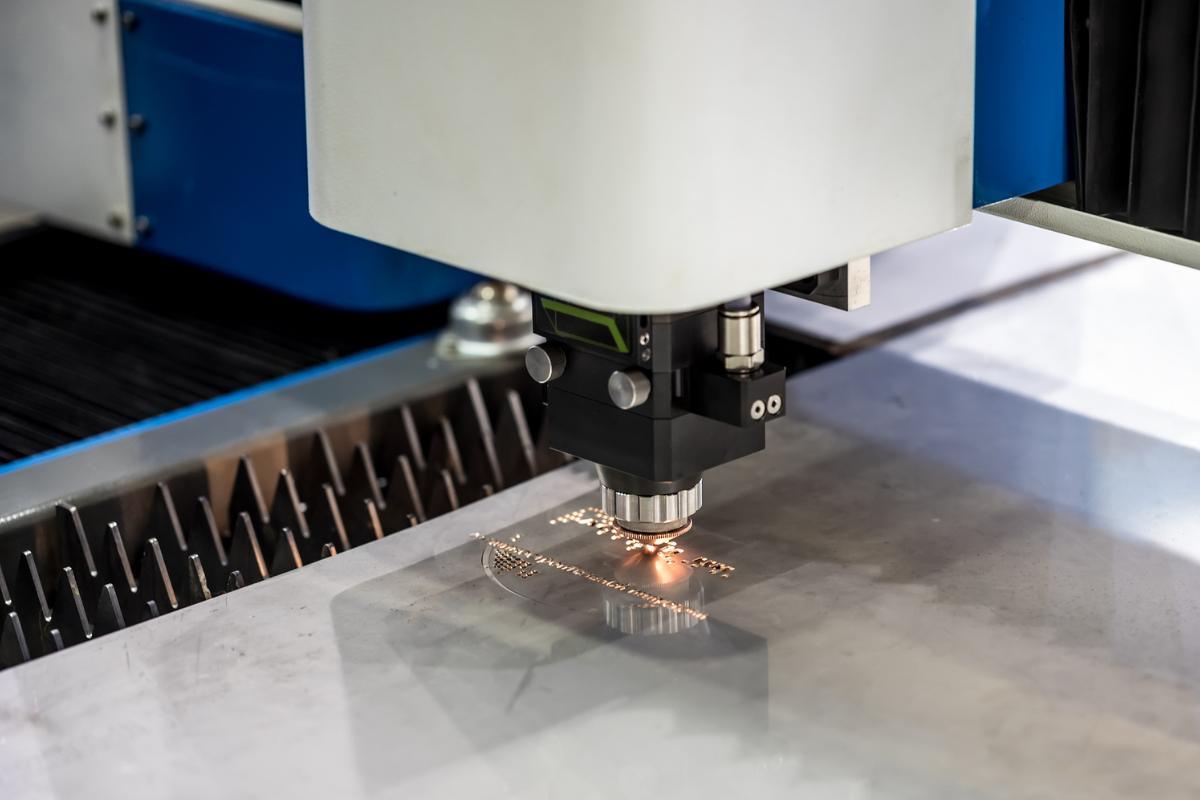

A Fiber Laser Marking Machine is a modern, non-contact technology that uses a high-power, concentrated fiber laser beam to create permanent marks. If you’re looking for a solution to mark text, serial numbers, or logos on metal, this speedy, precise, durable, and low-maintenance machine can be a real game-changer. It’s a masterful innovation for the automotive industry.

Wondering what its contribution is and how it’s applied? Let’s find out:

How Is Fiber Laser Marking Applied In The Automobile Industry?

Here’s why and how fiber laser marking has become widely used in the automotive industry:

- How is it used? This machine ensures the metal components are precisely marked, including exhaust systems, gears, and intricate body parts, without causing any distortion.

- Long-lasting: These machines are ideal for creating permanent, durable markings on steel, aluminum, and titanium. They ensure that identification marks on vehicle parts remain intact even under extreme temperatures, exposure to fluids, and abrasion throughout an automobile’s life cycle.

- Traceability: It is highly valued by auto manufacturers for labeling and tracking parts with unique serial numbers, barcodes, or QR codes.

- Speed: This high-speed technology enables mass, automated production lines.

- Anti-counterfeiting: Applying fiber laser marking is crucial to prevent parts counterfeiting, protect brand reputation, and ensure buyer safety.

Why Prakash Laser For Automotive Shock Absorbers? Here’s Why!

Here are the key features of Prakash Laser’s Fiber Laser Machines and the benefits they bring. Here’s why they are truly the best for Fiber Laser Marking job work:

- Our Fiber Laser Marking 20W Machine operates at a wavelength of 10.6 µm, with a marking speed of up to 7000 mm/s.

- It produces sharp, clean, and reliable markings on steel shock absorbers.

- The machine is operated by skilled experts, ensuring high-quality and fast results.

- It is highly effective for creating intricate designs.

- The laser head is sealed to prevent contamination of the optical chamber.

- The machine features a built-in cooling system.

How To Reach Prakash Laser For The Automotive Metal Laser Marking Job Work?

So, if you’re searching for ‘Fiber Laser Marking job work near me’ and everyone’s trying to sell you machines, don’t worry. If you’d rather not purchase a machine, you can always send your products to us for laser marking.

At Prakash Laser, we offer the best customized results and cost-effective solutions. We’re well-equipped for line integration, 2D code integration, and robot integration. Plus, we provide expert customer assistance, along with excellent, timely, and reliable after-sales support. Book a demo with us today, and we shall send you a quote at the earliest.

In Conclusion!

Finally, we’ll say it one more time: if precision, durability, and low maintenance for automotive shockers are what you’re after, partner with us. We ensure your satisfaction every step of the way and look forward to building a long-term partnership. We’re ready whenever you are!