Laser burn marks are one of those things that can quickly spoil an otherwise clean laser-cut project. You finish the cutting process, everything looks sharp, and then those dark edges or smoky marks show up. If you’re looking for how to get rid of laser burn marks, you’re probably dealing with scorched edges, surface residue, or discoloration that wasn’t part of the plan.

The good news is that most of these marks aren’t permanent. Once you understand why they show up, it becomes much easier to deal with them the right way. In this guide, you’ll learn how to tell different burn marks apart, what actually works to clean them up, and how a few small changes can help keep wood edges lighter and cleaner for your future laser cut operations. Let’s begin.

Table Of Contents

How To Get Rid Of Laser Burn Marks? Here Are Some Easy Steps

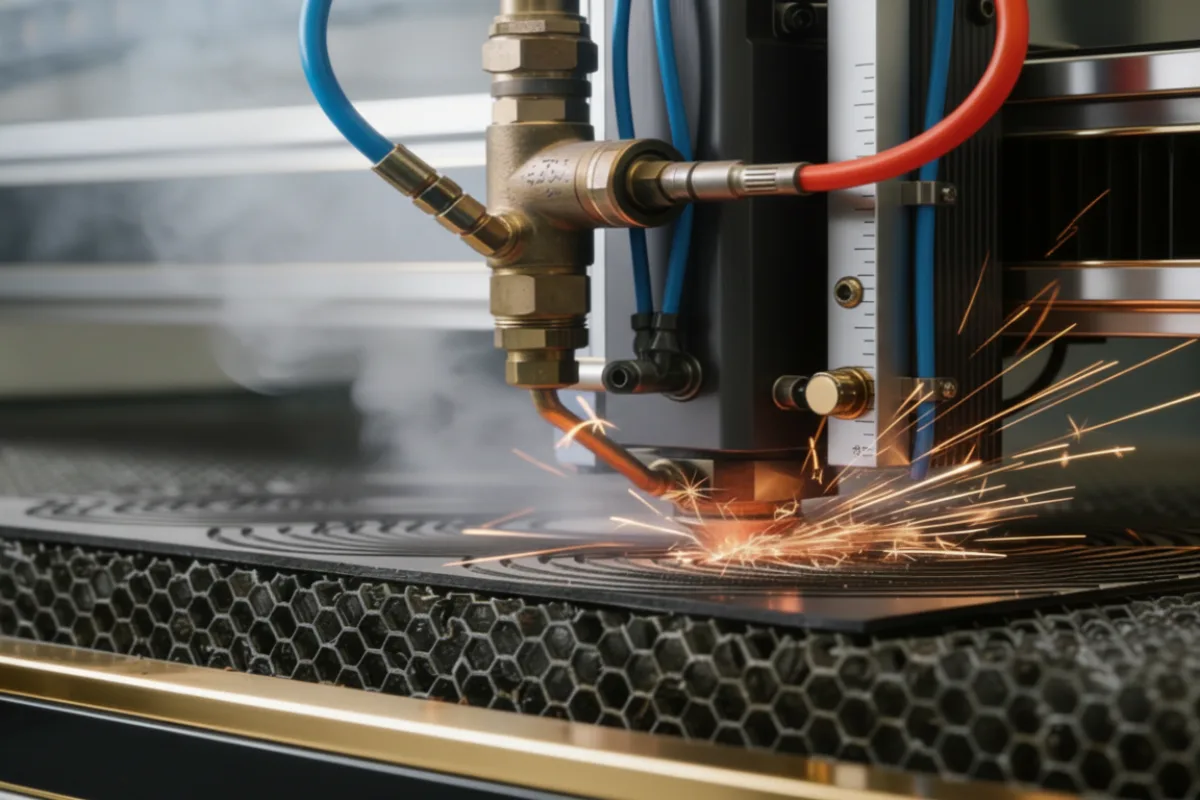

Laser burn marks usually show up when excess heat and smoke linger along the cut edges. But with a few smart adjustments to your CO2 Laser Cutting Machine setup, you can make a big difference and aim for cleaner, sharper cuts. So, here are some simple steps to help you understand how to remove laser burn marks from laser cut wood:

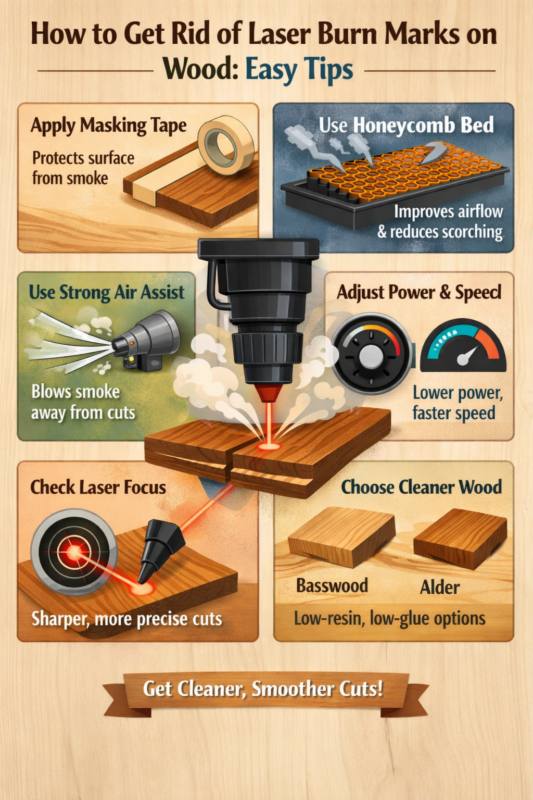

Step 1: Apply Masking Tape

Masking tape protects the wood surface from smoke residue during cutting. While it can’t stop heat-related edge darkening, it does prevent surface staining and speeds cleanup, especially on light-colored woods.

Step 2: Use A Honeycomb Bed

Using a honeycomb bed when laser cutting wood makes a noticeable difference. It allows smoke to pass through and escape from beneath the material, rather than lingering and settling along the cut edges. And if you’re wondering how to prevent scorching, this setup is one of the simplest and most effective. With better airflow beneath the wood, heat buildup is reduced, and laser-cut edges come out cleaner.

Step 3: Use Strong Air Assist

Air assist helps push smoke and debris away from the cut line before it settles back onto the wood. This reduces both heat buildup and surface staining, keeping edges lighter as the laser moves through the material.

Step 4: Adjust Power, Speed, and Frequency

High power and slow speeds increase heat exposure, which leads to darker edges. Therefore, lowering power, increasing speed, and reducing frequency or PPI help the laser cut efficiently without dwelling too long in one spot. When laser burning wood, this step deserves your full attention.

Step 5: Check And Maintain Proper Laser Focus

Next up in our how to get rid of laser burn marks guide is maintaining accurate laser focus. A properly focused CO2 laser cutter keeps the heat exactly where it is needed for the cut. If the focus is off, the heat spreads out, causing extra charring along the edges.

Step 6:Choose Low-Resin, Low-Glue Woods

Some woods naturally cut cleaner than others. Options like alder and basswood have lower resin content, which helps reduce burning and edge darkening. On the other hand, plywood and heavily glued materials tend to scorch more easily and leave darker edges behind. Understanding the nature of the wood you’re working with goes a long way when figuring out how to laser cut without burnt edges.

Identify The Type Of Laser Burn Before Fixing It

Before jumping into how to remove laser burn marks from wood, it’s important to understand what kind of burn you’re dealing with. Remember, not all laser burn marks are the same, and each type needs a different approach. For example:

- Light surface scorch: A thin layer of smoky residue that sits on the surface. It usually wipes off easily and doesn’t damage the wood.

- Moderate discoloration: Visible darkening that has slightly soaked into the wood. It won’t wipe off and usually needs light surface correction.

- Deep charred edges: Blackened, rough edges caused by prolonged heat exposure. This means the wood fibers have been burned and require additional corrective steps.

Therefore, identifying the type of burn first is highly essential. It helps you choose the right solution for how to clean laser engraved wood without overdoing it or damaging the surface.

Common Mistakes When Removing Laser Burn Marks

When cleaning up laser burn marks, minor missteps can make the problem worse instead of better. Avoid these common mistakes to protect both the look and structure of your wood.

- Don’t treat soot and char the same: Surface soot often wipes away easily, while charred wood needs more correction. Mixing the two can lead to unnecessary material removal.

- Avoid over-sanding the edges: Aggressive sanding can round off sharp edges and remove fine details, especially on engraved or precisely cut wood pieces.

- Don’t use aggressive methods too early: Jumping straight to heavy sanding or harsh cleaners can damage the wood. It’s best to start gently and work up only if needed.

How To Get Rid Of Laser Burn Marks The Right Way

Knowing how to get rid of black burn marks on wood isn’t about one quick solution. It’s about understanding what happens during laser cutting and making small, smarter adjustments along the way. Always remember, when you match the right cleanup approach with better cutting habits, your laser cut wood starts looking cleaner, more consistent, and much closer to what you pictured from the start.

1️⃣ Also, check out: Your Guide To CO2 Laser Marking Machines For Wood Engraving.

2️⃣ Watch our machine in action as it laser engraves a wooden pen.

Frequently Asked Questions

1. What causes laser burn marks on wood?

Laser burn marks form when too much heat and smoke stay around the cutting area. Slow speeds, high power, poor airflow, incorrect focus, or resin- and glue-heavy woods can cause the wood fibers to scorch rather than cut cleanly.

2. Does sanding damage engraved details?

Yes, it can if done too aggressively. Light sanding is usually safe for surface scorch marks, but heavy sanding can soften sharp edges and remove fine engraved details.

3. Is it better to fix burn marks or prevent them?

Prevention is usually more effective. Adjusting settings and airflow reduces the need for cleanup and helps maintain cleaner, more consistent cuts.

4. Can laser burn marks be removed entirely from wood?

It depends. Light surface burn marks can often be removed, while deeper charring may only be reduced. The final result depends on how deeply the wood fibers were affected during cutting.

5. Why do some laser cuts look clean while others burn badly?

Differences in wood type, thickness, focus, airflow, and settings affect how heat behaves, leading to uneven results.