Have you ever considered how different names or logos are marked on LED bulbs and lights? As a business owner, you should know how clear and sharp markings are made on LED bulbs and lights. There are, of course, advantages and disadvantages to both kinds of markings. Now, which is better, pad printing vs. laser marking? So, in this blog, we will look at which one is better and the advantages of the better marking technique. Which of the two should we choose: pad printing or laser marking?

What Is Pad Printing?

In pad printing for LED components, ink is transferred onto surfaces like LEDs or other surfaces. The ink is applied with a silicone pad. Pad printing has many advantages over laser marking, and in the quest for pad printing vs. laser marking, pad printing is better. Some of these are as follows:

Advantages Of Pad Printing

Being Economical

Pad printing is quite economical. Being economical means that large quantities of the same color LEDs can be made easily. So, when we have to choose between pad printing and laser marking, pad printing is better in terms of being economical.

Color Versatility

A wide variety and diversity of colors can be used with pad printing compared to laser marking. Therefore, if we must choose between pad printing and laser marking, pad printing is the winner in terms of color versatility. Various options exist, and logos and branding elements can be made onto the LED surfaces.

However, there are certain disadvantages to pad printing. Some of these are as follows:

Disadvantages Of Pad Printing

Lesser Of Details That Can Be Made Onto The Surfaces:

One cannot get detailed inscriptions onto the LED lights with pad printing. There is less attention paid to details and fine elements. So, if large quantities have to be made, it is impossible to maintain accuracy.

Time Cumbersome

You cannot get better results with large quantities using pad printing. So, it becomes time-consuming. It takes a lot of time, approximately 24-40 hours to make a pad ready for use. This is not required in laser marking process.

Durability Of Ink

The ink with pad printing is not durable. The ink used tends to fade over time and rubs off easily. It cannot make long-lasting marks.

Increased Costs

With pad printing, you need other things like ink and cleaning solutions. This leads to increased costs.

What Is Laser Marking?

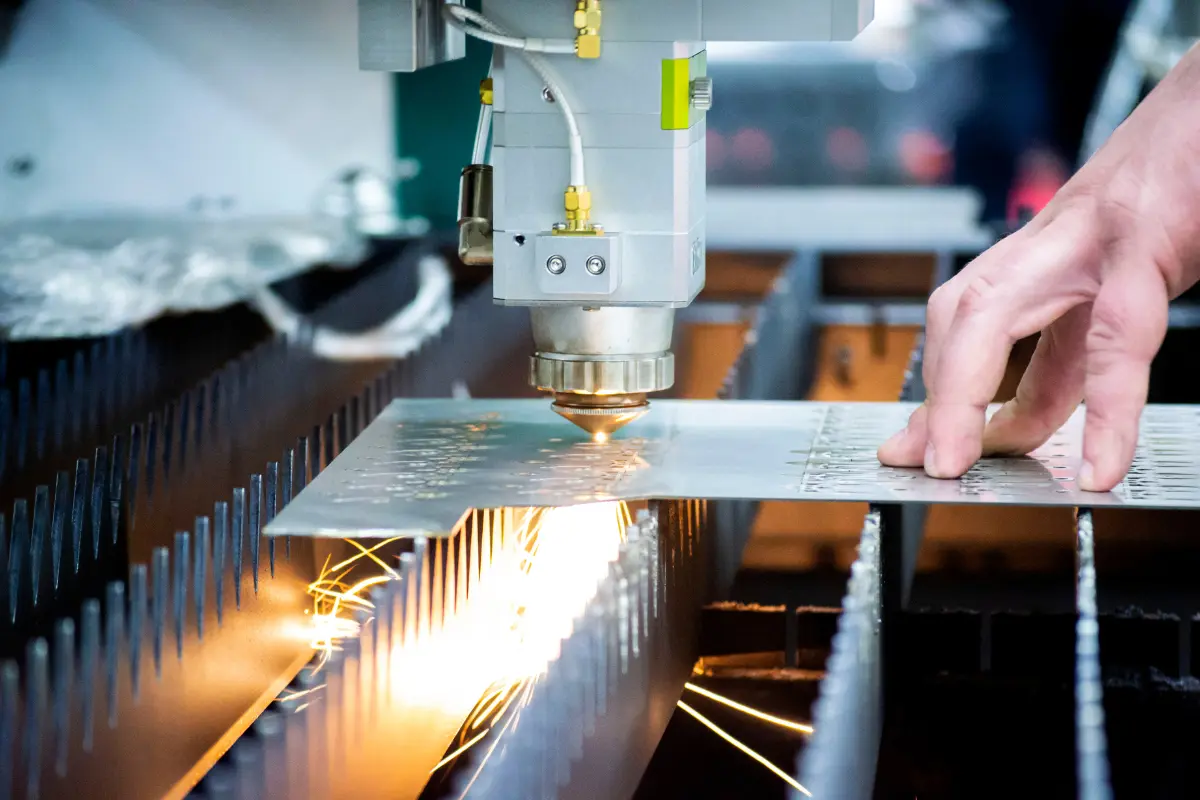

Laser marking for LED lights is a more detailed application. It uses a focused beam of light to mark the LED surface. Screens or molds are not required for laser marking. CAD is used to send the design through the machine’s software. It is a more flexible approach. It means that there is more scope for personalization or personalized design. Inks, paints, or solvents are not used in laser marking. Curing or drying steps are not there. The process is relatively fast and offers a wide range of options.

Advantages Of Laser Marking

High Precision And Detail

Greater attention is paid to precision and detailing in laser marking. Intricate designs can be achieved with laser marking. Small logos and thin lines are also achievable with this technique.

Permanent Marking for LED products

Laser marking gives a permanent imprint onto any surface. It cannot fade easily with time.

Faster Speeds

Laser marking is superior to older methods of marking. It is swift and precise. This is because the laser technology is of high quality. Laser marking uses a high-energy laser.

Environmental Friendliness

Inks and solvents are not used in laser marking.

Disadvantages

No Diverse Options

There is no diverse set of options available in terms of color. Mainly, colors like black that resonate with the LED surface are used.

Initial Expenditure Is Higher

The initial expenditure is higher than that of other approaches.

Pad Printing vs Laser Marking: What’s Better?

When we think about laser marking vs pad printing, laser marking is a better option than pad printing. The reasons are clear and as follows:

– Durability

This means that the marks are long-lasting. You do not need to worry as the marks do not fade with time. This leads to longevity in terms of usage.

– Versatility

You can change the content every other minute in laser marking which is not possible in pad printing in which the pad making procedure takes more than 24 hrs.

– Precision

Laser marking can give high-resolution characteristics. Intricate and precise details can be achieved easily. You can get complex logos as well as serial numbers.

– Effectiveness And Speed

Because the speed of laser marking is high, there is always scope for larger production volumes.

– Autogeneration feature

A serial number can be automatically generated in the laser marking process, assigning each piece a unique code, which is not possible with a pad printing machine.

– Keeping In Mind Environmental Concerns

Laser marking does not use ink or solvents. This makes it better to pay attention to the environment.

Conclusion

The best LED marking method is laser marking, not pad printing. So, if you are considering the debate on pad printing vs. laser marking, laser marking is the answer. Laser marking is better than pad printing. Laser marking is also suitable for environmental concerns. There are benefits like durability and speed. The speed with laser marking is high. The imprints of laser marking are long-lasting. If you want to know more about laser marking machines and how these are useful for LED marking, contact Prakash Laser now!