Laser engraving on stainless steel is one of the most reliable ways to add markings that last. In simple terms, it works by using a focused laser to interact with the surface. Sometimes it gently removes a thin layer of metal to create engraved lines. Other times, it slightly alters the surface so the marking stands out clearly with strong contrast. Fiber and infrared lasers are the go-to choices for stainless steel laser engraving, while other laser types may require specialized methods to achieve good results.

So, if you’re new to this, it can feel a bit overwhelming at first. That’s exactly why this guide keeps things simple. It discusses how the process works, why results can vary, and what you should know before you begin so that you can move into stainless steel engraving feeling prepared and confident. Let’s get started.

Table Of Contents

- How Does Stainless Steel Laser Engraving Work?

- Types Of Lasers Used For Stainless Steel Laser Engraving

- Stainless Steel Laser Engraving Process: Step-by-Step

- Common Applications Of Stainless Steel Laser Engraving

- Common Mistakes To Avoid When Laser Engraving Stainless Steel

- How To Choose The Right Laser Engraver For Stainless Steel

- Frequently Asked Questions

How Does Stainless Steel Laser Engraving Work?

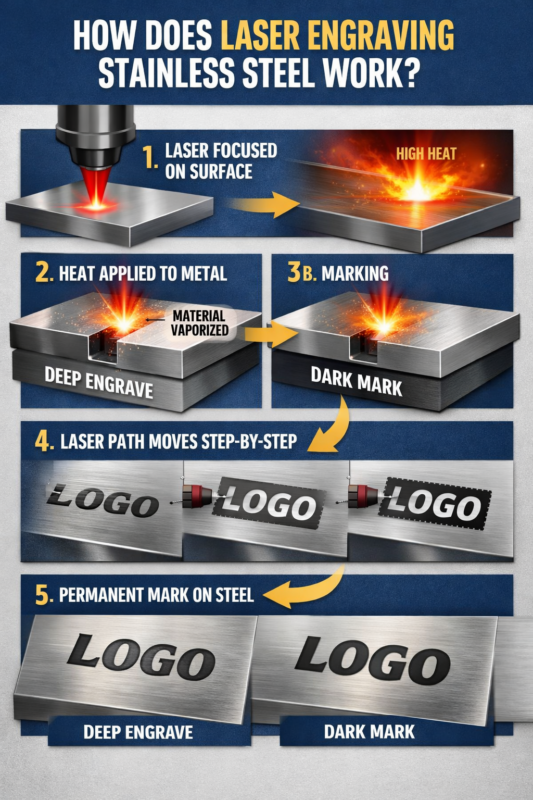

Stainless steel laser engraving is a software-controlled process where a laser follows a digital design to create permanent marks on the metal surface. The laser’s heat interacts with stainless steel in different ways, depending on the settings, enabling both surface marking and visual contrast.

- Laser etching on stainless steel uses lower laser power to heat the surface without removing material. This creates shallow, clean marks that are commonly used for text, logos, and fine details.

- Color engraving on stainless steel is done using advanced fiber lasers, such as MOPA systems. These lasers form thin oxide layers on the surface through controlled heating, which reflect light differently and produce visible colors, without the need for paints, coatings, or metal removal.

Types Of Lasers Used For Stainless Steel Laser Engraving

Fiber Laser Engraving For Stainless Steel

A Fiber Laser Engraving Machine is ideal when durability is a priority. And when questions like ‘will laser engraving wear off over time’ come up, the answer is usually no with this technology.

In short:

- This machine is the most effective and widely used option for stainless steel laser engraving

- It works directly on bare metal without coatings or sprays

- Typical power ranges from 20W to 100W+, depending on depth and speed requirements

- Delivers clean, sharp, and permanent engravings

CO2 Laser Engraving On Stainless Steel

CO2 laser engravers are best for cutting and engraving non-metal materials, but they can also engrave coated or plated metals.

Overall:

- Stainless steel does not absorb CO2 laser wavelengths well, so direct engraving isn’t possible. So, to mark stainless steel, a special coating or marking spray must be applied first.

- The laser bonds the coating to the surface rather than removing metal

- This creates a visible surface mark, not a deep or engraved result.

| Pro Tip:Before applying any marking spray or coating, thoroughly clean the stainless steel. Oils, dust, or fingerprints can prevent the coating from bonding evenly, leading to faded or patchy engraving. |

Stainless Steel Laser Engraving Process: Step-by-Step

Here’s a simple way to understand how to laser engrave stainless steel, especially if you’re new to the process and want clarity in simple steps.

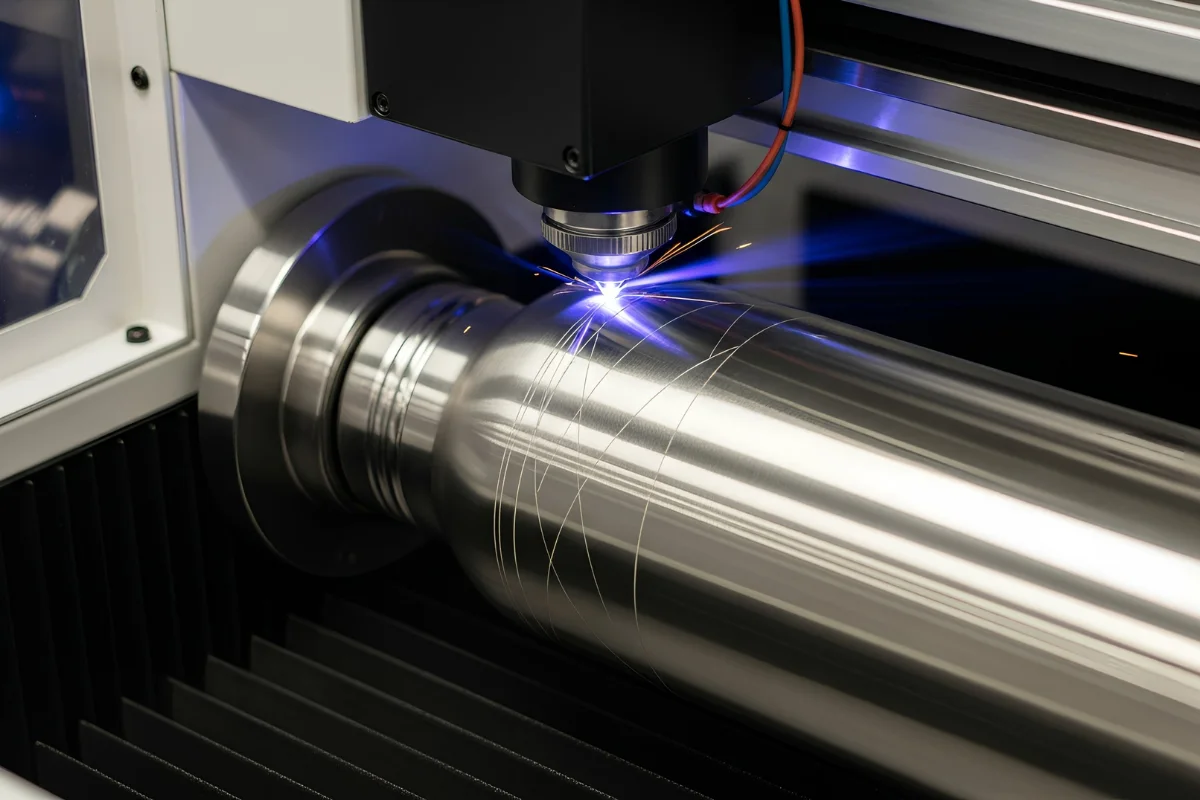

Step 1: Let the laser focus onto a tiny point on the stainless steel surface. This concentrates energy into a tiny area for precise control.

Step 2: The focused beam rapidly heats that spot; stainless steel reacts to this heat almost instantly.

Step 3: The surface changes based on the laser settings.

- For engraving, heat removes a thin layer of metal, creating real depth.

- For marking, the heat alters the top layer, creating contrast without much depth.

Step 4: The design is built line by line as the laser moves. The machine follows the digital file and repeats this process across the pattern.

Step 5: The final result depends on a few key controls, such as power, speed, focus, and stainless steel grade. It decides how dark, sharp, or deep the mark looks.

The mark stays long-term because it becomes part of the metal surface. There’s no ink or sticker involved, just a permanent change on stainless steel.

| Pro Tip: Always run a test first before starting the final engraving. It helps you catch any setting issues and avoid costly mistakes. |

Common Applications Of Stainless Steel Laser Engraving

Industrial And Manufacturing Uses

In industrial settings, stainless steel laser engraving is commonly used for part identification, serial numbers, and traceability marks. These engravings stay readable even in harsh environments, making them ideal for tracking components, meeting compliance needs, and maintaining long-term records without labels peeling or fading.

Commercial And Custom Products

For commercial use, laser engraving adds clear and professional markings to tools, tags, nameplates, and branded items. Businesses rely on it for consistent logos, product details, and custom information that looks clean and lasts through regular handling.

Decorative And Precision Work

Laser engraving is also popular for logos, fine text, and detailed textures. The precision of the laser allows for sharp lines and small details, making it suitable for both functional designs and visually refined finishes.

Common Mistakes To Avoid When Laser Engraving Stainless Steel

- Don’t use excessive power: Too much laser power can overheat the surface, causing rough edges, discoloration, or loss of detail instead of a clean mark.

- Don’t assume one setting fits all steel grades: Different stainless steel grades react differently to heat, so the same settings won’t always produce consistent results.

- Don’t skip test passes: Test runs help fine-tune settings and prevent permanent mistakes on the final piece.

- Confusing marking with engraving: Laser marking on stainless steel changes the surface appearance, while engraving removes material; mixing them up can lead to disappointing results.

How To Choose The Right Laser Engraver For Stainless Steel?

- Matching Machine Type To Your Use Case: Laser engraving systems scale by use. Hobbyists use low-power machines for light marking and small projects, small shops choose mid-range lasers for balanced speed and detail, and industrial setups rely on high-power lasers for deep engraving and high volume. More power boosts speed, while finer control improves precision.

- Key Features That Actually Matter: Reliable laser engraving depends on stable power for consistent results, precise pulse control for depth and finish, and dependable software for accurate, repeatable engraving.

So, lastly, think it through, assess your needs for laser engraving on stainless steel, and choose accordingly.

Also read: Aluminum Laser Engraving: Everything You Need To Know In 2025

Frequently Asked Questions

1. Why does stainless steel respond well to laser engraving?

Stainless steel engraves well because it withstands laser heat well. It resists warping or uneven melting, allowing clean, precise, and consistent markings.

2. Does Stainless Steel Grade Matter?

Yes. Different grades, such as 304 stainless steel or 316, respond differently to laser heat, which can affect the final look of the engraving.

3. Can a desktop laser engraver engrave stainless steel effectively?

Yes, desktop fiber lasers can engrave stainless steel, but they are best suited for shallow marks and smaller projects rather than heavy or high-volume work.

4. Does laser engraving weaken stainless steel?

No, laser engraving does not weaken stainless steel because it only alters a small, controlled surface area without affecting the metal’s overall structure or strength.

5. Can stainless steel be engraved without discoloration?

Yes, stainless steel can be engraved without discoloration by using proper laser settings that limit excess heat and focus only on controlled material removal.

6. Why does discoloration happen during stainless steel laser engraving?

Discoloration happens when excess heat causes oxidation on the steel surface, forming thin oxide layers that change how light reflects off the metal.