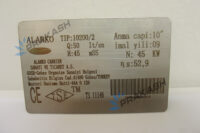

Precision-Based UV Laser Marking Machine For High-Detail Applications

UV Laser Marking Machine utilizes a short-wavelength laser to perform high-resolution marking without applying heat stress to the target material. This “cold marking” process allows for clean, sharp imprints on delicate surfaces such as plastics, glass, ceramics, and microelectronic components without making any hot zones on the surface. Due to their high accuracy and minimal material disruption, UV lasers are especially suited for industries requiring fine detailing and labeling. This works where high-density part identification, clarity, consistency, and traceability are critical.

Ready to mark with precision? Get the best price with Prakash Laser, the best UV Laser Marking Machine manufacturer in India.

Watch UV Laser Marking Machine

Standout Features Of UV Laser Marking Machine

- Minimal heat damage – ideal for heat-sensitive materials

- Long laser life – up to 50,000 hours for continuous, heavy-duty use

- Marks transparent materials like glass and plastic without warping

- Suitable for compact or densely packed components

- Low maintenance – no inks or solvents needed

- Consistent marking on curved or uneven surfaces

- High-speed marking for fast production lines

| MODEL | U.V Laser |

|---|---|

| LASER TYPE | U.V |

| LASER POWER | 3/5/10 WATT |

| LASER WAVELENGTH | 355 nm. |

| MARKING DEPTH | 0-1mm. |

| MARKING SPEED | <7000mm/s. |

| Min. LINE WIDTH | 0.01-0.2mm. |

| Min. CHARACTER SIZE | 0.015mm. |

Rotary attachment

Fixtures as per component

Marking area of 200×200 or 300×300 or bigger size

| Materials | Yes |

|---|---|

| Acrylic | √ |

| Wood | √ |

| Foam | √ |

| Brass | √ |

| Paper | √ |

| Rubber | √ |

| Marble | √ |

| Plastics | √ |

| Cast Iron | √ |

| Stainless steel | √ |

| Leather | √ |

| Zinc Alloy | √ |

| Copper | √ |

| Nickelage | √ |

| Galvanization | √ |

| Aluminium | √ |

| Titanium | √ |

Industries That Rely On Our UV Laser Marking

The UV laser marking machine are used across various industries where precision and damage-free marking is essential. Below are some of the key sectors that benefit from this technology:

– Electronics Industry

UV laser marking is ideal for precise, non-damaging engraving on PCBs, microchips, and connectors. The cold marking process ensures readability and traceability on sensitive electronic components without heat distortion.

– Medical Sector

In the medical field, UV lasers are beneficial because they enable sterile, permanent markings on devices like syringes, tubes, and surgical tools, which are crucial for compliance and traceability in regulated environments.

– Automotive Industry

Automotive suppliers implement UV Laser Marking to mark plastic components, dashboard panels, and interior parts with part numbers and serial codes, ensuring long-lasting identification on sensitive materials.

– Pharmaceuticals and Packaging

Pharmaceutical manufacturers rely on UV laser marking machines for high-contrast codes, expiration dates, and batch IDs on foil packs, labels, and transparent packaging, adding product authentication and safety.

– Consumer Goods and Plastics

UV laser systems provide clean branding and tracking codes on plastic casings and home appliances, offering manufacturers durable, high-resolution marks with low-cost laser markings.

– Semiconductor Industry

The most crucial employment of the UV Laser Marking Machine is in the semiconductor sector, which enables ultra-fine coding on wafers and IC chips. The precise, low-impact beam is ideal for marking without compromising microelectronic performance and ensuring the quality of lasting marks.

On What Types Of Materials Do Our UV Laser Marking Machine Work Best?

Our UV Laser Marking Machine can be used for multifunctional operations in a range of industries because they are made to mark a variety of materials, particularly those that are heat-sensitive or need fine detailing. UV lasers provide clean, non-contact marking without causing surface damage on materials including ceramics, rubber, glass, coated metals, and transparent plastics.

From microelectronic components, pharmaceutical packaging, or medical-grade plastics, these machines get a tick through all the boxes. This technology delivers accurate, permanent results with minimal distortion, making it a dependable solution for high-precision identification and traceability needs.

Unlock High-Precision, Reliable Marking With UV Laser Technology

Prakash Laser’s best UV Laser Marking Machines offer industry-grade precision for growing businesses to those looking to expand clean, damage-free marking on sensitive materials. Designed for versatility and built with cutting-edge technology, these machines deliver high-contrast results across plastics, ceramics, glass, and coated surfaces.

If you’re evaluating options based on features and UV Laser Marking Machine price, our team is here to guide you. Get in touch today to learn which model suits your application best—precision and value are just a conversation away.